What should we pay attention to when cleaning and maintaining the cam divider?

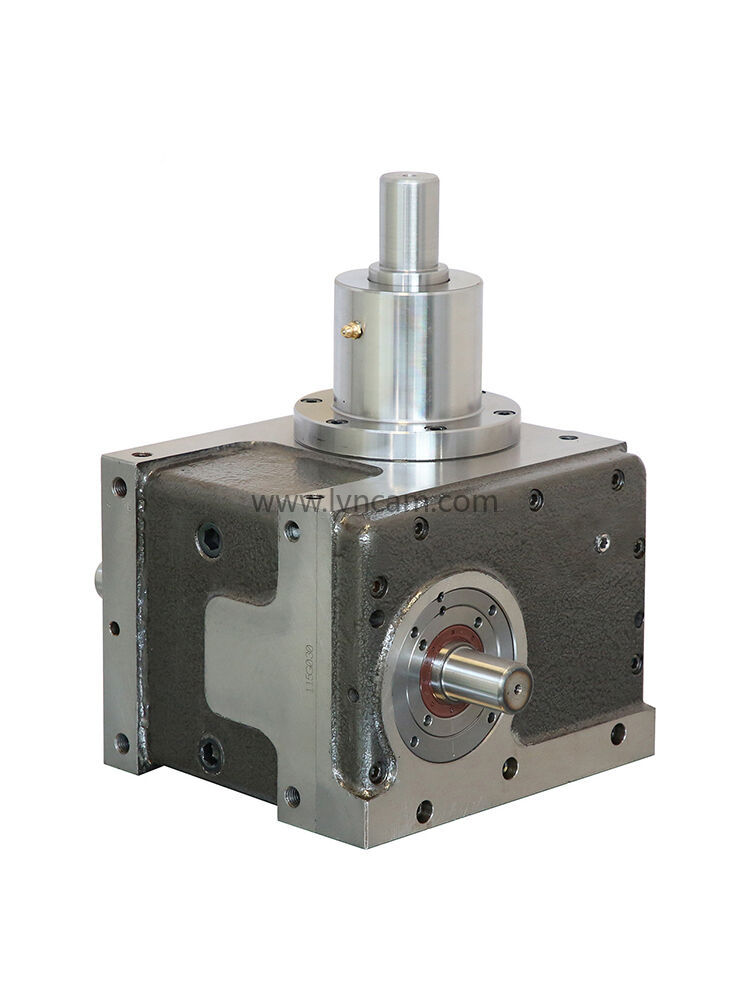

Cam dividers can bring a lot of convenience to our production, but no matter how good the product is, if you want to use it for a longer and more stable time, later cleaning and maintenance as well as reasonable use and care are indispensable. If it is overused and not maintained, then even the best product will accelerate the reduction of its service life. What should be paid attention to in the cleaning and maintenance of cam dividers? Let's talk about it here.

First of all, it is very important to regularly remove dust and dirt from the cam divider. If the environment is relatively poor, it is necessary to use basic cleaning fluid after each use to avoid affecting the normal operation of the equipment. The basic cleaning method is also relatively simple, just use a dust-free soft cloth or compressed air for cleaning. If it is a thorough cleaning, then it is necessary to disassemble the external detachable parts and do a detailed cleaning. It should be noted that some parts cannot be exposed to water. If it is really dirty, then it is necessary to use alcohol cotton pads to clean it, and then wipe it with a clean soft cloth, but be careful not to use hard iron brushes and other items to clean it, so as not to scratch the parts.

In terms of maintenance, there are many things to pay attention to when adding lubricating oil. If the lubricating oil inside the cam divider is insufficient and not replenished in time, it will cause great wear and tear to the machine. At the same time, the lubricating oil cannot be added at will. It should be matched with the cam divider. The viscosity, quality and replenishment amount are all standardized. Generally speaking, the first lubricating oil should be replaced after the equipment has been running for 1000 hours, and then every 3000 hours. If you are not very familiar with it, you can also operate it according to the manual of the cam divider equipment.

The following points should be noted when cleaning and maintaining the cam divider:

1. Regular cleaning: Use a dust-free soft cloth or compressed air for basic cleaning. For dirty parts, you can use alcohol cotton pads to wipe them, but do not use hard iron brushes and other items.

2. Thorough cleaning: If thorough cleaning is required, the external detachable parts need to be disassembled and cleaned carefully.

3. Adding lubricating oil: Insufficient lubricating oil will cause great wear and tear to the machine. When adding lubricating oil, it is necessary to match it with the cam divider. The first replacement should be after the equipment has been running for 1000 hours, and then every 3000 hours. You can also operate according to the equipment manual.

related articles

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow