PRODUCTS

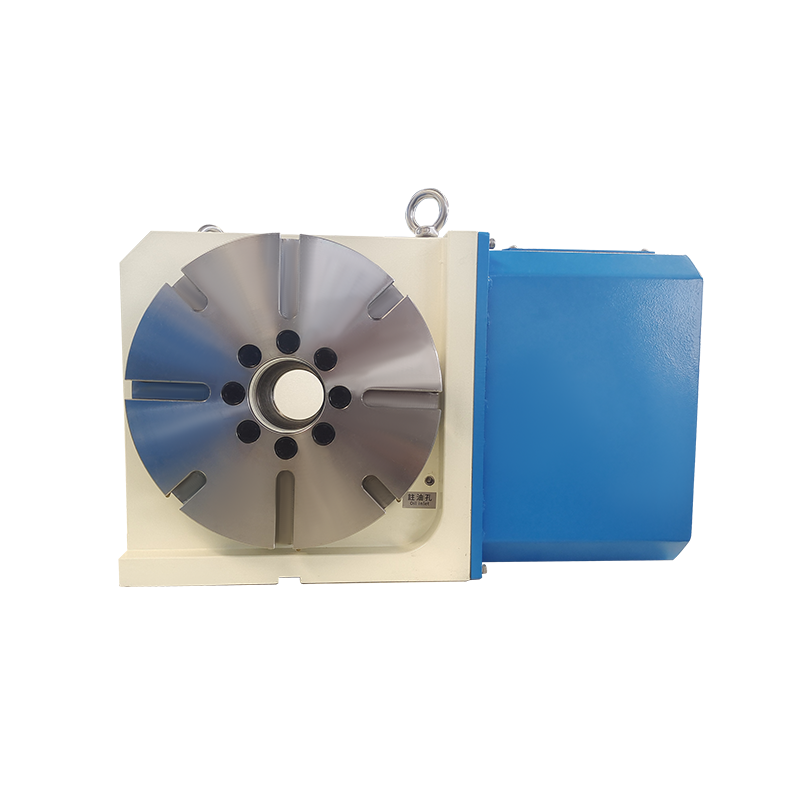

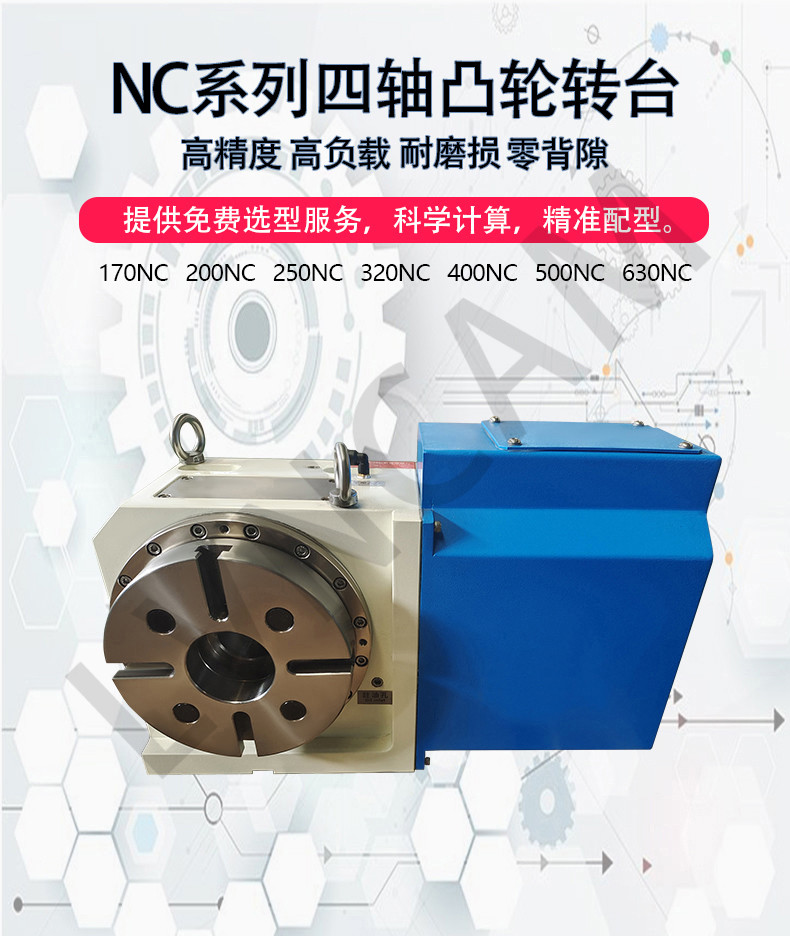

LNA200R Roller Cam Servo CNC Rotary Table

【advantage】

The cam roller CNC turntable has the working characteristics of high precision, high speed, zero backlash and heavy load. The constant speed driving surface of the input shaft arc cam and the pre-loaded rolling contact transmission of the needle bearing on the output turret achieve zero backlash and high-speed operation of the turntable. The rolling transmission has almost zero friction movement, so that the cam roller CNC turntable can maintain backlash-free transmission and high-precision positioning for a long time, and does not require regular calibration and adjustment. The output shaft of the four-axis turntable uses a circular outer wall larger than the bearing set on the shaft, and the two ends of the cam input shaft are set with double bearings, which further enhances the stability and load capacity of the turntable, can better cope with high speed and heavy cutting force during processing, improve the accuracy of processed workpieces, improve work efficiency, and reduce production costs.

Shandong Luning Precision Machinery Consulting Telephone