To improve the efficiency of the machining center, you can take the following methods and suggestions:

1. Optimize the process flow: Analyze and optimize each step in the processing process, find and eliminate possible bottlenecks. Simplify cumbersome operations, reduce unnecessary processes, and reasonably arrange the workpiece processing route to improve overall efficiency.

2. Reasonable production plan: According to the product demand and the production capacity of the processing center, the production plan should be reasonably arranged. Try to avoid the idleness and idling of the processing center to ensure the continuous operation of the production line.

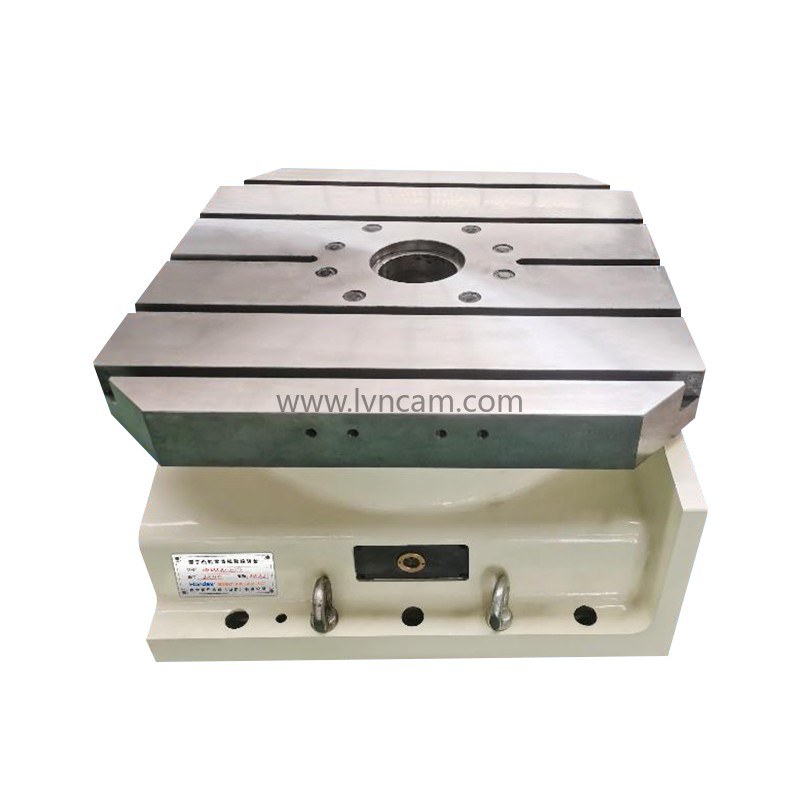

3. Efficient use of the workbench: Reasonably arrange the layout and fixation of the workpiece to maximize the use of the workbench space of the machining center. At the same time, use tools such as fixtures and positioning devices to improve the efficiency of clamping and unloading.

4. Choose appropriate tools and workpiece materials: Choose appropriate tools and workpiece materials according to processing requirements. Choose efficient cutting edges to improve cutting efficiency and tool life. Choose workpiece materials with excellent performance and good processability to reduce cutting resistance during processing.

5. Automation and intelligence: Introduce automation equipment and intelligent systems to realize automation, full automation or semi-automation of machining centers, such as automatic clamping, automatic tool change, automatic measurement, etc., to improve production efficiency and product quality.

6. Increase the utilization rate of the machining center: Try to avoid downtime and idle time of the machining center. Rationally arrange equipment maintenance and care to improve equipment reliability and stability. Rationally arrange production plans and management processes to reduce equipment idle time.

7. Personnel training and skills improvement: Strengthen personnel training and skills improvement to improve the professional level and work efficiency of operators. Through flexible and diverse training methods, operators can master the operating skills and process requirements of the machining center.

8. Use advanced CNC systems and software: Introduce advanced CNC systems and software to provide more efficient and intelligent processing control and programming functions. Improve the automation and intelligence level of the processing process by optimizing program writing and processing adjustment functions.

9. Continuous improvement and learning: Strengthen the study and research of the relevant technologies and processes of the machining center, and pay attention to the latest trends and technological developments in the industry. In practice, continuously summarize and improve the working methods and management models of the machining center to improve efficiency and production benefits.

Please note that the situation of each machining center may be different, so when implementing these methods and suggestions, reasonable adjustments and optimizations should be made according to the actual situation.

related articles

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow