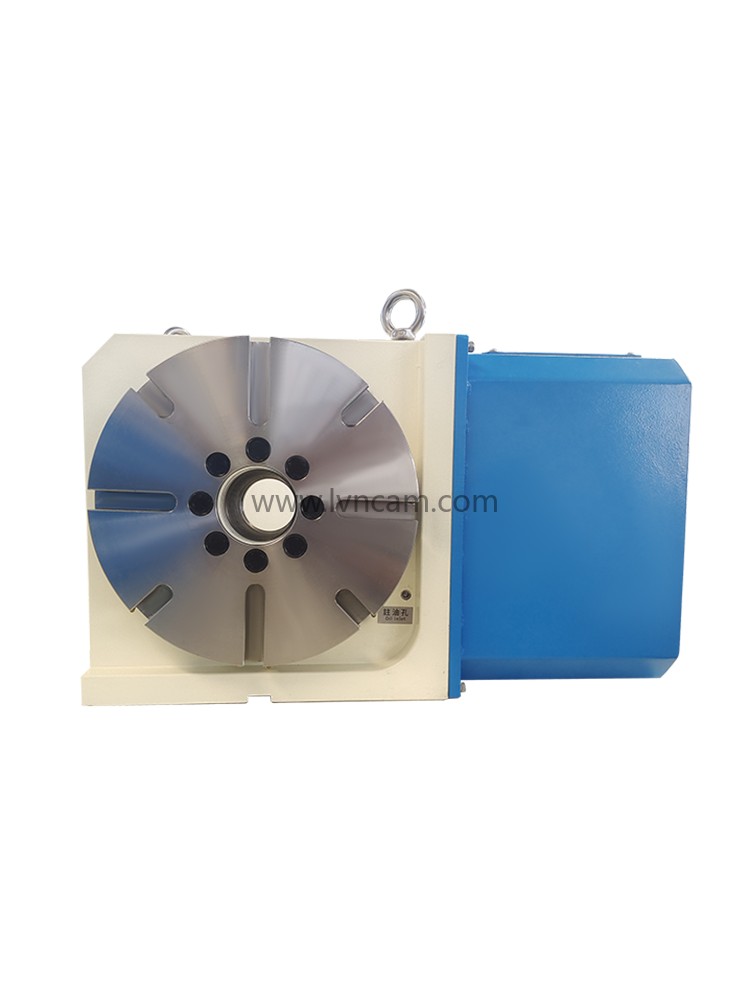

The CNC rotary table is an important part of CNC machine tools and has the following functions and effects:

1. Carrier clamping: The CNC rotary table can be used to clamp the workpiece, fix it on the worktable, and ensure the stability of the workpiece during processing.

2. Rotational motion: The CNC rotary table can realize rotational motion through the control system, so that the workpiece rotates in the horizontal direction. This rotational motion can be used to complete certain special process requirements, such as circular processing, spiral processing, etc.

3. Positioning and Angle Setting: CNC rotary tables can help machine tools achieve precise positioning and angle setting of workpieces. By accurately controlling the rotation angle and position, the workpiece can be processed at a specific angle, ensuring the accuracy and repeatability of the processing results.

4. Multi-station processing: CNC rotary tables usually have multiple working positions, which can clamp multiple workpieces at the same time and realize the function of simultaneous processing. This can improve production efficiency and reduce operation time.

5. Automatic control: The CNC rotary table can be linked with the CNC control system to achieve automatic processing and production. The machine operator can control the movement and processing of the table by simply inputting instructions.

The CNC rotary table of machine tools can provide higher flexibility and precision in the processing process by controlling the rotation, positioning and angle setting of the workpiece, providing important support for CNC machine tools to realize various process operations.

related articles

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow