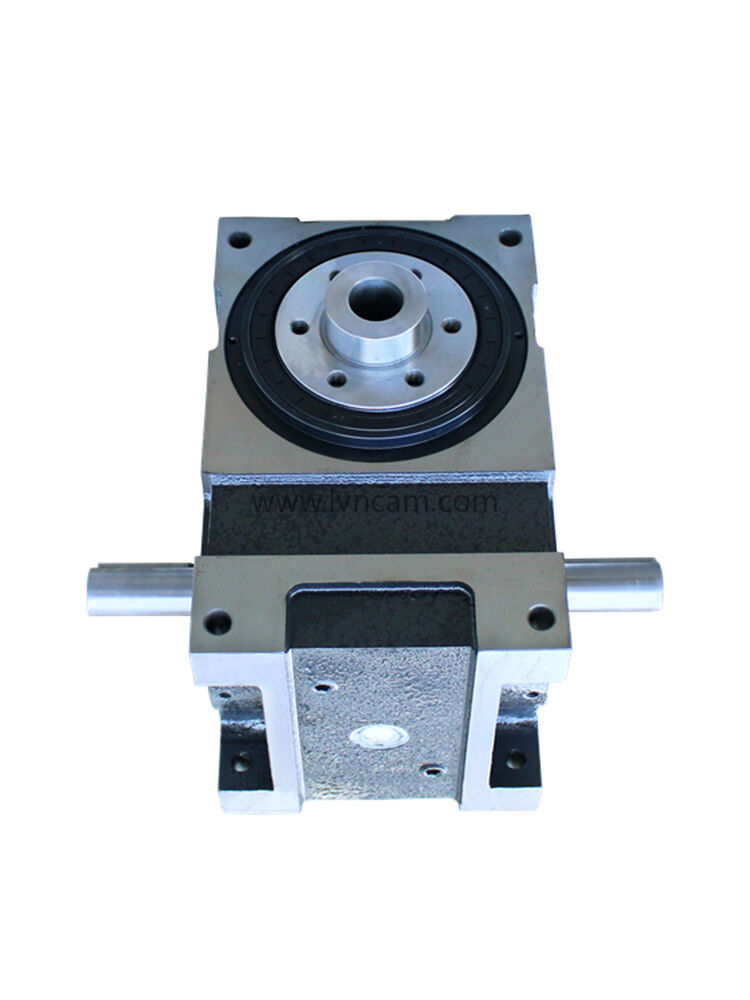

The installation method of the cam divider is as follows:

1. Installation of the machine:

(1) The cam divider has been precisely processed and adjusted. Users are not allowed to disassemble or adjust it before use.

(2) Check whether the mounting surface of the divider is damaged. If so, use an oilstone to repair it.

(3) Determine the position of the input and output shafts, fill the positioning pins, and tighten the screws evenly.

(4) Since the divider is subject to pulsating load torque, it must be installed firmly and stably.

Since the installation surface of the cam divider has a high requirement for verticality or parallelism relative to the input and output shafts, the installation base must ensure that the input and output shaft directions of the divider are coaxial with the input and output directions required by the equipment, and cannot be deflected or eccentric. If the installation is incorrect, it will not only affect the output accuracy, but also cause serious damage to the divider because the divider is in an abnormal stress state at this time.

2. Installation of input and output shafts:

Regarding the connecting parts associated with the input and output shafts of the divider, they must have the characteristics of good rigidity in the direction of rotation, no reverse impact and stable rotation.

When installing turntables, sprockets, pulleys, gears, flanges, etc. associated with the input and output shafts of the divider, the following points should be noted:

(1) Do not use a hammer to hit or make unreasonable impacts to avoid damaging the cam and needle bearing inside the divider.

(2) The input and output shafts and their external rigid shafts must not be operated arbitrarily and must be fully center adjusted.

(3) The input and output shafts are finely machined H6 grade shafts, and the hole diameter is finely machined to H6 grade, which has an ideal press-in effect. Avoid extreme deviations between the hole and the shaft, and the key connection cannot be too loose.

(4) When installing processing parts, accessories, fixtures and tools, it is necessary to use instruments to detect and adjust to eliminate eccentricity or process step errors relative to the workbench.

The above installation points and precautions can ensure the stable operation and high-precision segmentation effect of the cam divider, and protect the divider from damage. Please be sure to comply with the above installation requirements when using the cam divider.

related articles

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow