The accuracy of the cam divider depends on many factors, such as the materials used, design and manufacturing process. Generally speaking, the accuracy of the cam divider can reach a range of tens to several microns. The specific accuracy requirements are determined according to the actual use requirements and may vary depending on the application field. If you have specific requirements for the accuracy of a specific cam divider, you can refer to the technical specifications of the relevant product or consult a professional manufacturer for more accurate information.

In addition to materials, design and manufacturing processes, there are other factors that affect the accuracy of the cam divider. For example, the roundness, straightness and surface quality of the camshaft have an important influence on the accuracy of the divider. At the same time, environmental factors such as temperature and humidity when the cam divider is used will also affect its accuracy.

In order to ensure the accuracy of the cam divider, manufacturers usually use advanced processing equipment and technology, such as CNC machining, precision grinding, etc. In addition, strict quality control measures are also required in the manufacturing process, such as detection technology and the use of tooling.

The accuracy requirements of cam dividers may vary for specific application areas. For example, cam dividers in automotive engines require very high accuracy to ensure accurate valve opening and closing times. In other areas, the accuracy requirements may be relatively low.

In short, the accuracy of the cam divider depends on many factors, and the specific accuracy requirements should be determined according to actual needs and application areas. If you have specific requirements, it is recommended to consult relevant professional manufacturers or check product technical specifications for more accurate information.

related articles

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

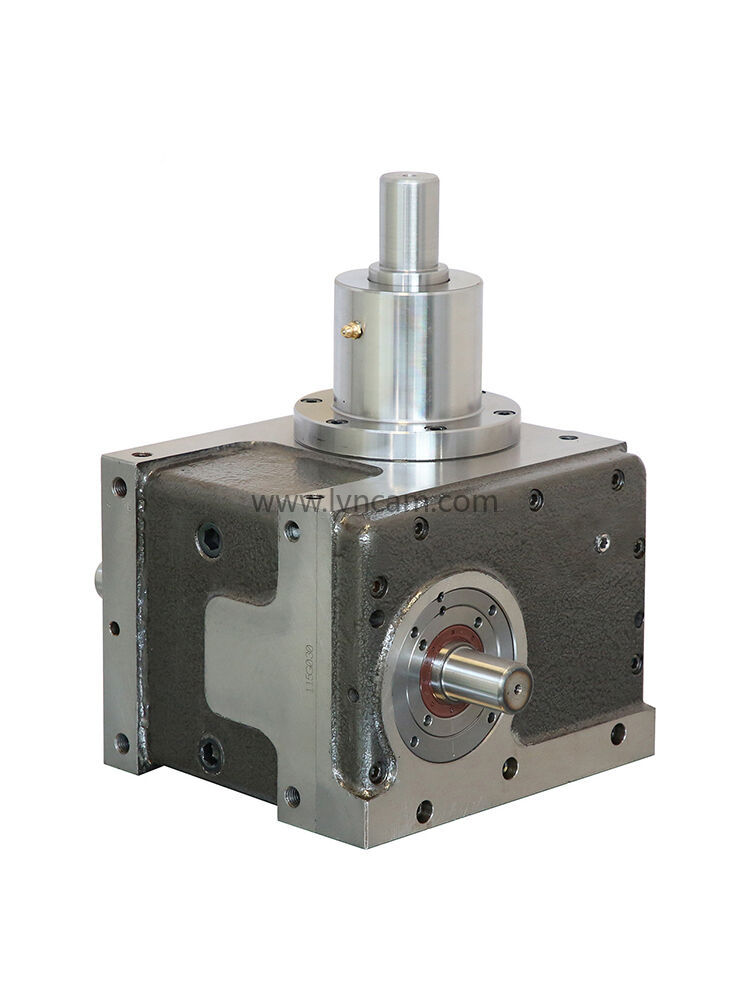

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow