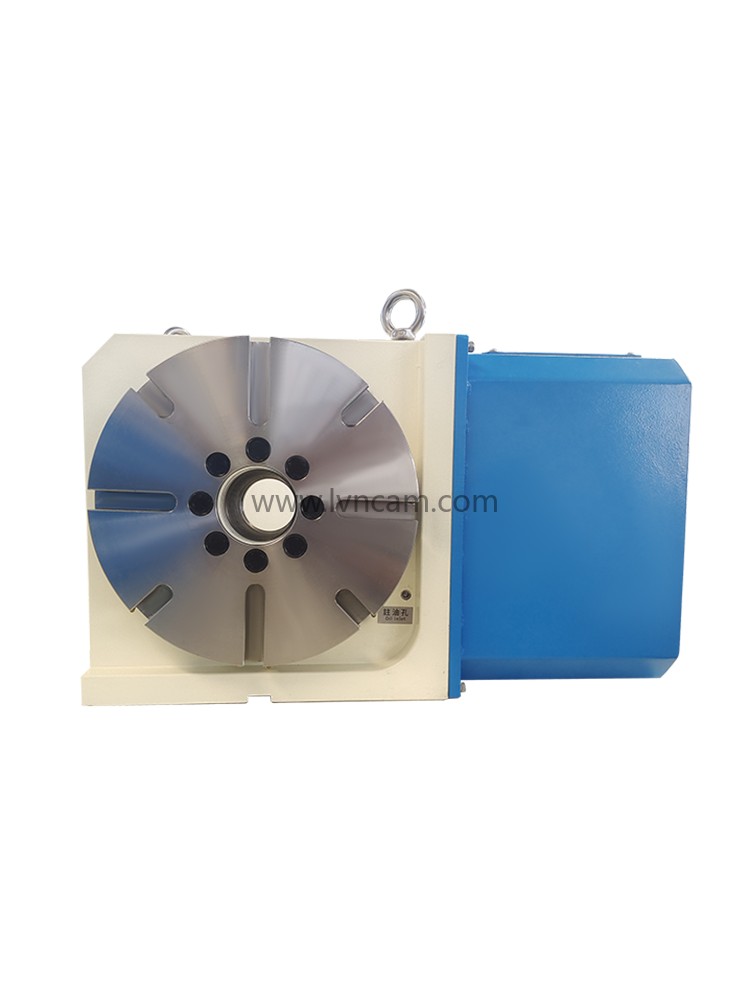

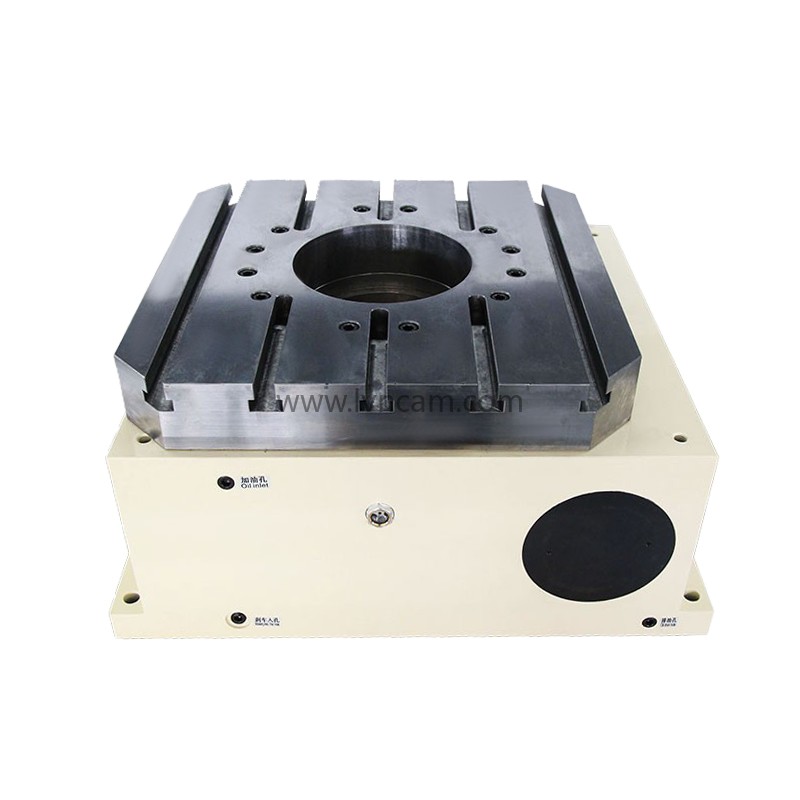

CNC rotary tables are indispensable equipment in modern factories. They use computer programs to control mechanical movement, bringing many advantages to production. This article will focus on the three advantages of CNC rotary tables in production: improving production efficiency and product quality, reducing the labor intensity of staff, and strong adaptability.

In traditional pure manual production, defective products and omissions may occur. However, the introduction of CNC rotary tables can effectively avoid these problems. Through automated production and reducing manual operation errors, the consistency of production is ensured, and the number of defective products is reduced, thereby improving production efficiency and product processing accuracy.

At the same time, the CNC rotary table can also reduce the labor intensity of the staff and make them more labor-saving. This not only reduces the factory's personnel investment and labor costs, but also improves the work quality and comfort of the staff.

In addition, CNC rotary tables have strong adaptability and can meet the production needs of different industries and products. It is easy to assemble, easy to maintain, and does not require a lot of space and manpower. Therefore, many factories choose to use CNC rotary tables to improve production efficiency and flexibility, and customize and program different styles of CNC rotary tables according to needs.

In summary, CNC rotary tables bring many advantages to production, including improving production efficiency and product processing accuracy, reducing the labor intensity of staff, and having strong adaptability. Choosing a regular and reliable manufacturer to purchase CNC rotary tables is an important means to ensure equipment quality and service. By introducing CNC rotary tables, factories can achieve higher efficiency and better product quality in the production process, thereby promoting the development of the enterprise.

related articles

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow