news

The origin and development of the cam divider What are the uses of the indexing plate (indexing box)2023-07-05The cam divider is also called intermittent divider, intermittent indexer, cam intermittent machine, divider, indexer, indexing box, cam indexing box, cam intermittent box. The world's first indexing plate (indexing box) was born in May 1926 and has a history of nearly a hundred years.

The origin and development of the cam divider What are the uses of the indexing plate (indexing box)2023-07-05The cam divider is also called intermittent divider, intermittent indexer, cam intermittent machine, divider, indexer, indexing box, cam indexing box, cam intermittent box. The world's first indexing plate (indexing box) was born in May 1926 and has a history of nearly a hundred years. Download the floor plan and 3D drawings of 250DF of Shuning Automation2023-06-22Download the floor plan and 3D drawings of Shuning Automation 250DF, high-definition drawings in PDF format. For 3D drawings, please scan the QR code to add customer service staff to provide the latest version of the drawings.

Download the floor plan and 3D drawings of 250DF of Shuning Automation2023-06-22Download the floor plan and 3D drawings of Shuning Automation 250DF, high-definition drawings in PDF format. For 3D drawings, please scan the QR code to add customer service staff to provide the latest version of the drawings. How to identify inaccurate positioning caused by cam divider collision2023-06-22During the use of the divider, it is necessary to ensure that it is started and stopped in the stationary position. During the rotation process, collisions and starts and stops in the driving position must be avoided. Starting and stopping in a position other than the stationary position is considered abnormal use. Abnormal use can cause great damage to the divider and lead to inaccurate positioning. In severe cases, it can cause the internal needle roller bearing to break. When the cam divider is not positioned accurately and the disc shakes, how can you tell whether it is caused by a collision or starting and stopping in a non-stationary position? If the inaccurate positioning, gap, and shaking are caused by a collision, usually only the bearings and indexing holes corresponding to the workstation where the collision occurred have problems. As shown in the video below, only the outer rings of two needle roller bearings are deformed and the indexing holes are deformed.

How to identify inaccurate positioning caused by cam divider collision2023-06-22During the use of the divider, it is necessary to ensure that it is started and stopped in the stationary position. During the rotation process, collisions and starts and stops in the driving position must be avoided. Starting and stopping in a position other than the stationary position is considered abnormal use. Abnormal use can cause great damage to the divider and lead to inaccurate positioning. In severe cases, it can cause the internal needle roller bearing to break. When the cam divider is not positioned accurately and the disc shakes, how can you tell whether it is caused by a collision or starting and stopping in a non-stationary position? If the inaccurate positioning, gap, and shaking are caused by a collision, usually only the bearings and indexing holes corresponding to the workstation where the collision occurred have problems. As shown in the video below, only the outer rings of two needle roller bearings are deformed and the indexing holes are deformed. Analysis of the Causes of Cam Divider Shaft Breakage2023-06-22The force shaft of the divider in the picture is connected to the power source through a connecting rod. The fracture of the input shaft has a lot to do with the force mode. It is recommended that customers measure the horizontality of the connecting rod. When the input shaft of the divider and the connecting rod cannot remain horizontal, the shaft will easily break.

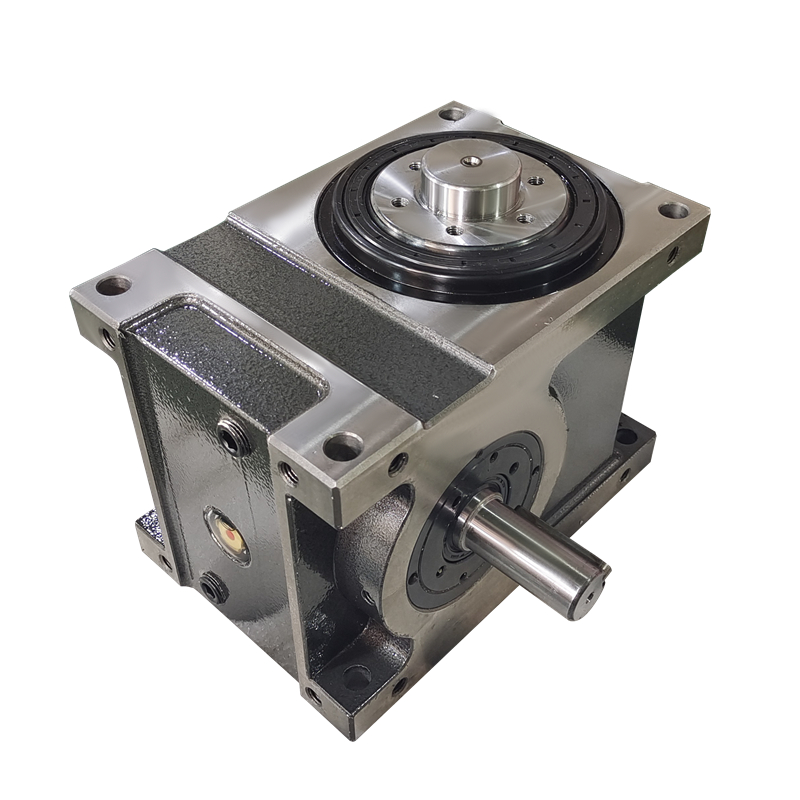

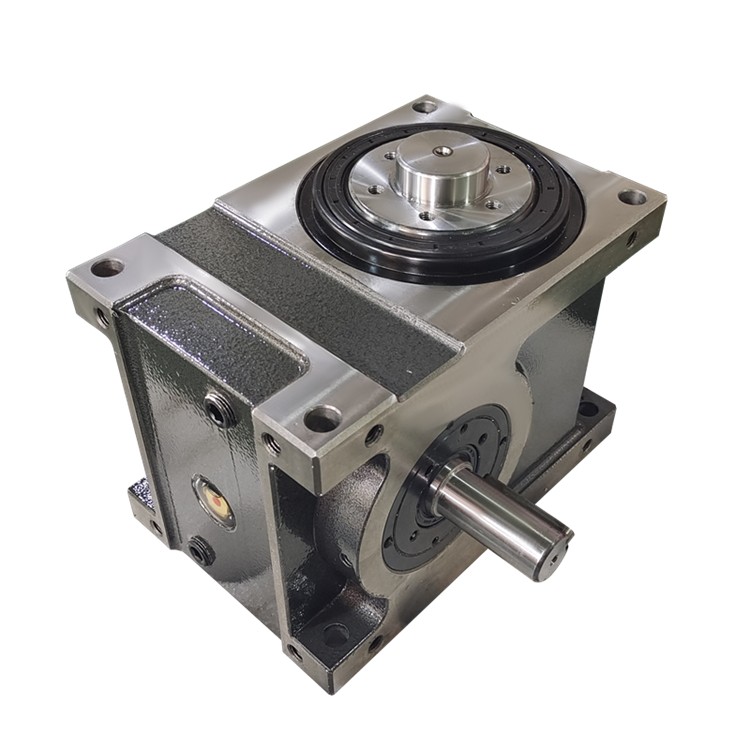

Analysis of the Causes of Cam Divider Shaft Breakage2023-06-22The force shaft of the divider in the picture is connected to the power source through a connecting rod. The fracture of the input shaft has a lot to do with the force mode. It is recommended that customers measure the horizontality of the connecting rod. When the input shaft of the divider and the connecting rod cannot remain horizontal, the shaft will easily break. Things to note when choosing a platform desktop cam divider2023-06-22When you choose a platform desktop cam divider, you need to pay attention to the hole spacing of the bottom fixed holes. Taking 80DT as an example, note that the hole spacing at A is the same as the hole spacing at B.

Things to note when choosing a platform desktop cam divider2023-06-22When you choose a platform desktop cam divider, you need to pay attention to the hole spacing of the bottom fixed holes. Taking 80DT as an example, note that the hole spacing at A is the same as the hole spacing at B. 25DS 32DS Small Pocket Cam Divider2023-06-22At present, our company's small cam dividers can achieve 25, 32 center distances, 25DS, 32DS. 1. Cam divider selection; 2. Cam divider start and stop position adjustment; 3. Cam divider replacement breather cap; 4. Cam divider replacement lubricant;

25DS 32DS Small Pocket Cam Divider2023-06-22At present, our company's small cam dividers can achieve 25, 32 center distances, 25DS, 32DS. 1. Cam divider selection; 2. Cam divider start and stop position adjustment; 3. Cam divider replacement breather cap; 4. Cam divider replacement lubricant;

{item.title}

{item.publish_time}

{item.description}

common problem

- LN125R roller cam CNC turntable servo turntable real shot

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow

- RU90DA-2-240-X-HL001 Ultra-thin platform desktop cam divider (DA)