Cam dividers are currently divided into three categories:

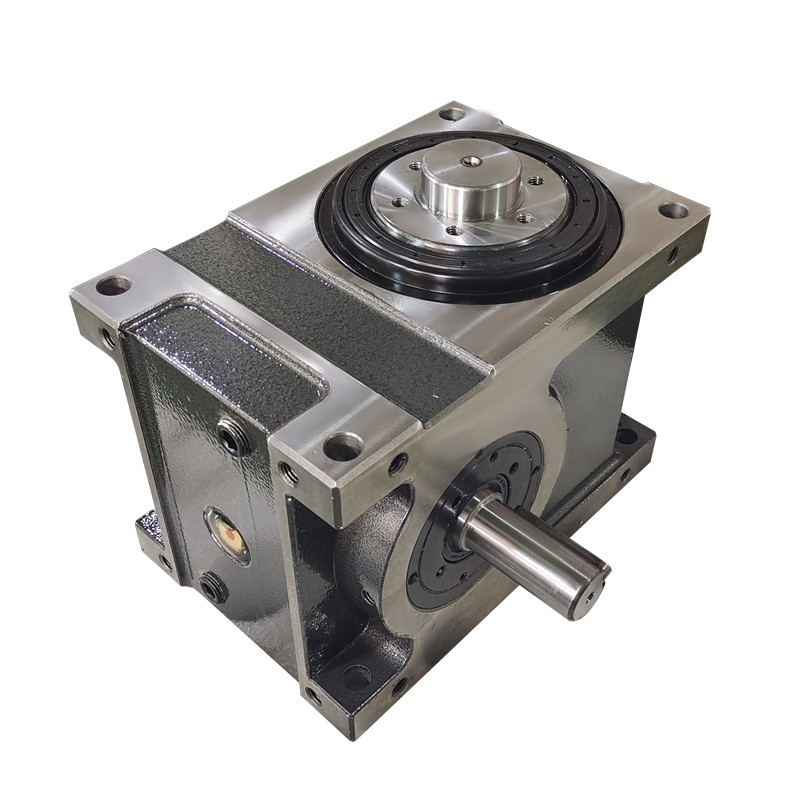

Curved type, our common DF DT DA DS DFH DFS DE etc. all belong to the curved series;

The flat type, also called the parallel conjugate type, is a rectangular block in appearance. It is mainly shaft-driven and is often used in die-cutting machine industry and in applications that require chain drive.

Cylindrical type, some manufacturers use BU to represent cylindrical series dividers, and some use Y to represent them. Cylindrical dividers are mostly used in heavy load industries, such as electric welding robots, automotive welding industry, pancake machine industry, etc.

Today, taking the common curved divider as an example, let ’s talk about the selection of the divider .

The application data required for splitter selection can be summarized into four aspects:

Disc diameter;

Total load weight, including disc weight and workpiece weight;

The number of workstations, for example, 2 workstations, 4 workstations, 6 workstations, can reach hundreds of workstations;

Speed includes two aspects: indexing time and dwelling time. One is the time taken to move from station 1 to station 2. The other is the dwelling time, or the workpiece processing time.

After providing the above four aspects of information, import the data into the selection software, and the corresponding splitter model will be automatically calculated. In this way, the model selected through scientific calculation is appropriate, and you will not waste money and space by choosing a large one, nor will you be unsustainable by choosing a small one.

When purchasing a splitter, in addition to choosing the right splitter model, what other issues should you pay attention to?

related articles

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow