news

Pushing the boundaries: Cam dividers usher in the next generation of transportation2023-08-12Cam dividers are an innovative technology that plays an important role in the field of transportation. By converting linear motion into rotary motion, cam dividers improve power transmission efficiency and save energy. Its application in engines and transmission systems makes power output more stable and reliable, and it also demonstrates the advantages of high precision, controllability and intelligence in electric vehicles and unmanned driving technology. The advancement of cam divider technology and its application promotion will bring new breakthroughs and changes to the development of transportation.

Pushing the boundaries: Cam dividers usher in the next generation of transportation2023-08-12Cam dividers are an innovative technology that plays an important role in the field of transportation. By converting linear motion into rotary motion, cam dividers improve power transmission efficiency and save energy. Its application in engines and transmission systems makes power output more stable and reliable, and it also demonstrates the advantages of high precision, controllability and intelligence in electric vehicles and unmanned driving technology. The advancement of cam divider technology and its application promotion will bring new breakthroughs and changes to the development of transportation. Improving efficiency: How cam dividers change manufacturing processes2023-08-12The application of cam dividers plays an important role in improving the efficiency of the manufacturing industry. Through automation, intelligence and adaptive technology, it achieves precise processing, reduces manpower input and loopholes in the production process, and makes the manufacturing process more efficient and precise. Cam dividers are widely used in the fields of automobile manufacturing, electronic equipment manufacturing and food processing, promoting the improvement of production efficiency and product quality. With the continuous development of technology, cam dividers will continue to play an important role in the manufacturing industry and promote the progress and development of the industry.

Improving efficiency: How cam dividers change manufacturing processes2023-08-12The application of cam dividers plays an important role in improving the efficiency of the manufacturing industry. Through automation, intelligence and adaptive technology, it achieves precise processing, reduces manpower input and loopholes in the production process, and makes the manufacturing process more efficient and precise. Cam dividers are widely used in the fields of automobile manufacturing, electronic equipment manufacturing and food processing, promoting the improvement of production efficiency and product quality. With the continuous development of technology, cam dividers will continue to play an important role in the manufacturing industry and promote the progress and development of the industry. "Flipping the Past: Machine Tool Refurbishment Technology Brings New Opportunities to the Manufacturing Industry"2023-08-11Machine tool refurbishment is the process of returning old machine tools to production lines to improve performance and reliability. It includes steps such as evaluation and analysis, parts replacement and upgrades, technical improvements, testing and debugging. Machine tool refurbishment provides companies with an affordable and feasible way to extend the service life of machine tools, improve production efficiency and reduce costs. At the same time, machine tool refurbishment reduces resource waste and plays a positive role in environmental protection. Through machine tool refurbishment, companies can enjoy the same performance and quality as new equipment, bringing new opportunities and competitive advantages.

"Flipping the Past: Machine Tool Refurbishment Technology Brings New Opportunities to the Manufacturing Industry"2023-08-11Machine tool refurbishment is the process of returning old machine tools to production lines to improve performance and reliability. It includes steps such as evaluation and analysis, parts replacement and upgrades, technical improvements, testing and debugging. Machine tool refurbishment provides companies with an affordable and feasible way to extend the service life of machine tools, improve production efficiency and reduce costs. At the same time, machine tool refurbishment reduces resource waste and plays a positive role in environmental protection. Through machine tool refurbishment, companies can enjoy the same performance and quality as new equipment, bringing new opportunities and competitive advantages. The secrets of CNC machine tool handling skills are revealed, and exclusive techniques help you save time and effort2023-08-10The key to moving a machine tool is to be well prepared, make a plan, choose the right tools, adjust the center of gravity and pay attention to safety. By following these steps, you can complete the task of moving a machine tool easily and safely. If you encounter difficulties, it is recommended to seek help from professional movers.

The secrets of CNC machine tool handling skills are revealed, and exclusive techniques help you save time and effort2023-08-10The key to moving a machine tool is to be well prepared, make a plan, choose the right tools, adjust the center of gravity and pay attention to safety. By following these steps, you can complete the task of moving a machine tool easily and safely. If you encounter difficulties, it is recommended to seek help from professional movers. A comprehensive review of machine tool models: different uses, different choices!2023-08-09This article details the features and advantages of different machine tool models. From drilling machines, lathes, milling machines, grinders to planers, we discuss their working principles, application scopes, and key features. By reading this article, readers can gain an in-depth understanding of various machine tool models and provide a reference for choosing the right machine tool. The correct machine tool selection will have a positive impact on production efficiency and product quality. I hope this article can provide readers with useful guidance in the process of machine tool selection.

A comprehensive review of machine tool models: different uses, different choices!2023-08-09This article details the features and advantages of different machine tool models. From drilling machines, lathes, milling machines, grinders to planers, we discuss their working principles, application scopes, and key features. By reading this article, readers can gain an in-depth understanding of various machine tool models and provide a reference for choosing the right machine tool. The correct machine tool selection will have a positive impact on production efficiency and product quality. I hope this article can provide readers with useful guidance in the process of machine tool selection. Analysis of CNC machine tool application cases: successful practices in various industries2023-08-08CNC machine tools are indispensable key equipment in the manufacturing industry. By using digital control technology and automation systems, they provide precise, efficient and reliable processing solutions. CNC machine tools play an important role in industries such as automobile manufacturing, aerospace and electronic product manufacturing. They achieve high-precision processing, rapid production and personalized customization, and improve production efficiency and product quality. With the advancement of technology, CNC machine tools will become more intelligent and efficient, bringing new development opportunities to the manufacturing industry.

Analysis of CNC machine tool application cases: successful practices in various industries2023-08-08CNC machine tools are indispensable key equipment in the manufacturing industry. By using digital control technology and automation systems, they provide precise, efficient and reliable processing solutions. CNC machine tools play an important role in industries such as automobile manufacturing, aerospace and electronic product manufacturing. They achieve high-precision processing, rapid production and personalized customization, and improve production efficiency and product quality. With the advancement of technology, CNC machine tools will become more intelligent and efficient, bringing new development opportunities to the manufacturing industry. Is your machine tool overheating? Stay calm, there are solutions!2023-08-07This article introduces methods to solve the problem of high machine tool temperature. Starting from identifying the problem, maintaining the cooling system, optimizing the machine tool layout and using auxiliary measures, it explains in detail how to control the machine tool temperature. By regularly checking and maintaining the cooling system, rationally laying out the machine tool, using insulation materials and auxiliary equipment, etc., the machine tool temperature can be reduced to ensure the stability and improvement of production efficiency and product quality.

Is your machine tool overheating? Stay calm, there are solutions!2023-08-07This article introduces methods to solve the problem of high machine tool temperature. Starting from identifying the problem, maintaining the cooling system, optimizing the machine tool layout and using auxiliary measures, it explains in detail how to control the machine tool temperature. By regularly checking and maintaining the cooling system, rationally laying out the machine tool, using insulation materials and auxiliary equipment, etc., the machine tool temperature can be reduced to ensure the stability and improvement of production efficiency and product quality. Can the indexing plate have an odd number of stations?2023-08-05Can a dividing plate have an odd number of positions? The answer is yes, a dividing plate can have an odd number of positions. A dividing plate is a device used to rotate a workpiece and achieve precise division. The workpiece is fixed on the dividing plate and rotated by manual or electric means. There are usually many equally divided scales and positions on the dividing plate, which are used to accurately position and divide the workpiece.

Can the indexing plate have an odd number of stations?2023-08-05Can a dividing plate have an odd number of positions? The answer is yes, a dividing plate can have an odd number of positions. A dividing plate is a device used to rotate a workpiece and achieve precise division. The workpiece is fixed on the dividing plate and rotated by manual or electric means. There are usually many equally divided scales and positions on the dividing plate, which are used to accurately position and divide the workpiece. How much does a cam divider cost? How should I choose one?2023-08-05The price of a cam divider varies depending on the brand, model, specification and supplier. In the market, the price of a cam divider usually ranges from a few hundred yuan to several thousand yuan. You can get the most accurate information about the specific price by consulting the supplier or checking the relevant product sales platform. At the same time, factors such as transportation, installation and after-sales service should also be considered to fully evaluate the cost of the cam divider. It is recommended that you conduct market research before purchasing, compare the prices and product quality of multiple suppliers, and choose the cam divider with the best cost performance.

How much does a cam divider cost? How should I choose one?2023-08-05The price of a cam divider varies depending on the brand, model, specification and supplier. In the market, the price of a cam divider usually ranges from a few hundred yuan to several thousand yuan. You can get the most accurate information about the specific price by consulting the supplier or checking the relevant product sales platform. At the same time, factors such as transportation, installation and after-sales service should also be considered to fully evaluate the cost of the cam divider. It is recommended that you conduct market research before purchasing, compare the prices and product quality of multiple suppliers, and choose the cam divider with the best cost performance. How many surfaces can the CNC turning table process?2023-08-05The CNC turning table is a kind of equipment used for machining, which can realize multi-faceted machining of workpieces during machining. The CNC turning table can turn and rotate the workpiece in different directions by electric or hydraulic means to facilitate machining.

How many surfaces can the CNC turning table process?2023-08-05The CNC turning table is a kind of equipment used for machining, which can realize multi-faceted machining of workpieces during machining. The CNC turning table can turn and rotate the workpiece in different directions by electric or hydraulic means to facilitate machining. How to choose a CNC machine tool? There are 6 factors you should consider2023-08-04When choosing a CNC machine tool, you can consider the following factors: 1. Processing requirements: First, you need to clarify the type, size, material and processing technology of the workpiece to be processed. Different workpieces require different types of CNC machine tools for processing, such as lathes, milling machines, drilling machines, etc. 2. Processing accuracy: Choose a suitable CNC machine tool according to the accuracy requirements of the workpiece. Generally speaking, high-precision processing requires more precise CNC machine tools, while for some simple workpieces, ordinary precision machine tools can be selected. 3. Production efficiency: Consider the production needs.

How to choose a CNC machine tool? There are 6 factors you should consider2023-08-04When choosing a CNC machine tool, you can consider the following factors: 1. Processing requirements: First, you need to clarify the type, size, material and processing technology of the workpiece to be processed. Different workpieces require different types of CNC machine tools for processing, such as lathes, milling machines, drilling machines, etc. 2. Processing accuracy: Choose a suitable CNC machine tool according to the accuracy requirements of the workpiece. Generally speaking, high-precision processing requires more precise CNC machine tools, while for some simple workpieces, ordinary precision machine tools can be selected. 3. Production efficiency: Consider the production needs. How to choose cutting tools for CNC rotary tables? These 7 factors must be kept in mind!2023-08-04The key points of selecting CNC rotary table tools include: 1. Processing material: Select the appropriate tool material and type according to the hardness, strength and cutting performance of the material. 2. Cutting type: Select the appropriate cutting type according to the processing requirements, such as milling, drilling, boring, etc. 3. Cutting parameters: Determine the parameters such as cutting speed, feed speed, cutting depth, etc. according to the processing conditions, and then select the corresponding tool. 4. Wear resistance: Select tools with good wear resistance to improve processing efficiency and tool life. 5. Stability: Select tools with strength and rigidity to ensure a stable cutting process and processing accuracy. 6. Tool geometry: Select tools that meet the processing requirements, considering factors such as edge angle, top angle, and edge shape. 7. Economy and substitutability: Consider the price, life and substitutability of the tool, and select a tool with a high cost performance. Taking the above factors into consideration, selecting suitable CNC rotary table tools can improve processing efficiency, accuracy and economic benefits.

How to choose cutting tools for CNC rotary tables? These 7 factors must be kept in mind!2023-08-04The key points of selecting CNC rotary table tools include: 1. Processing material: Select the appropriate tool material and type according to the hardness, strength and cutting performance of the material. 2. Cutting type: Select the appropriate cutting type according to the processing requirements, such as milling, drilling, boring, etc. 3. Cutting parameters: Determine the parameters such as cutting speed, feed speed, cutting depth, etc. according to the processing conditions, and then select the corresponding tool. 4. Wear resistance: Select tools with good wear resistance to improve processing efficiency and tool life. 5. Stability: Select tools with strength and rigidity to ensure a stable cutting process and processing accuracy. 6. Tool geometry: Select tools that meet the processing requirements, considering factors such as edge angle, top angle, and edge shape. 7. Economy and substitutability: Consider the price, life and substitutability of the tool, and select a tool with a high cost performance. Taking the above factors into consideration, selecting suitable CNC rotary table tools can improve processing efficiency, accuracy and economic benefits. What are the common causes of damage to cam dividers? What are the solutions?2023-08-03To summarize briefly, the reasons for the damage of cam dividers include material quality problems, processing quality problems, overload or incorrect application during use. Solutions include replacement of high-quality materials, optimization of manufacturing processes, correct use and application, and regular maintenance and inspection. The specific solution should be selected according to the specific situation, and you can consult professionals for more accurate and effective solutions.

What are the common causes of damage to cam dividers? What are the solutions?2023-08-03To summarize briefly, the reasons for the damage of cam dividers include material quality problems, processing quality problems, overload or incorrect application during use. Solutions include replacement of high-quality materials, optimization of manufacturing processes, correct use and application, and regular maintenance and inspection. The specific solution should be selected according to the specific situation, and you can consult professionals for more accurate and effective solutions. Six precision indicators for CNC turntable inspection2023-08-03Which precision indicators are tested for CNC turntables? The main precisions of CNC turntables include position accuracy, repeatability, self-alignment, angle accuracy, parallelism, and verticality. These precisions are used to evaluate the motion accuracy and stability of the turntable in different aspects. By measuring and testing these precisions, it can be ensured that the motion of the CNC turntable meets the requirements and improve its accuracy and stability.

Six precision indicators for CNC turntable inspection2023-08-03Which precision indicators are tested for CNC turntables? The main precisions of CNC turntables include position accuracy, repeatability, self-alignment, angle accuracy, parallelism, and verticality. These precisions are used to evaluate the motion accuracy and stability of the turntable in different aspects. By measuring and testing these precisions, it can be ensured that the motion of the CNC turntable meets the requirements and improve its accuracy and stability. Analysis of the causes of vibration of the hollow rotating platform may have five common situations2023-08-03The reasons for the shaking of the hollow rotating platform are analyzed as follows: 1. Assembly problems: poor assembly or poor fit causes shaking. 2. Unbalanced mass: Uneven mass distribution causes unbalanced centrifugal force. 3. Transmission system problems: Transmission system failure or wear causes shaking. 4. External force interference: External vibration, vibration or impact interference causes shaking. 5. Processing technology problems: Incorrect processing technology causes shaking. Solutions include adjusting assembly, balancing mass, maintaining the transmission system, eliminating external force interference and improving processing technology.

Analysis of the causes of vibration of the hollow rotating platform may have five common situations2023-08-03The reasons for the shaking of the hollow rotating platform are analyzed as follows: 1. Assembly problems: poor assembly or poor fit causes shaking. 2. Unbalanced mass: Uneven mass distribution causes unbalanced centrifugal force. 3. Transmission system problems: Transmission system failure or wear causes shaking. 4. External force interference: External vibration, vibration or impact interference causes shaking. 5. Processing technology problems: Incorrect processing technology causes shaking. Solutions include adjusting assembly, balancing mass, maintaining the transmission system, eliminating external force interference and improving processing technology.

{item.title}

{item.publish_time}

{item.description}

Industry Information

- 2024 Dragon Boat Festival Holiday Notice

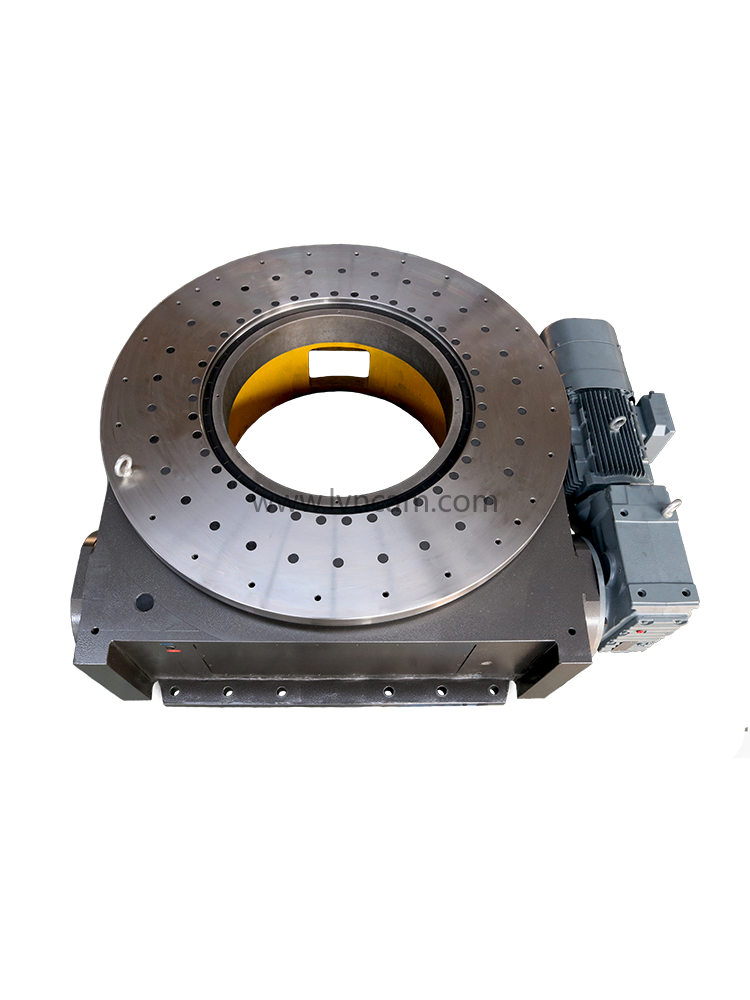

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

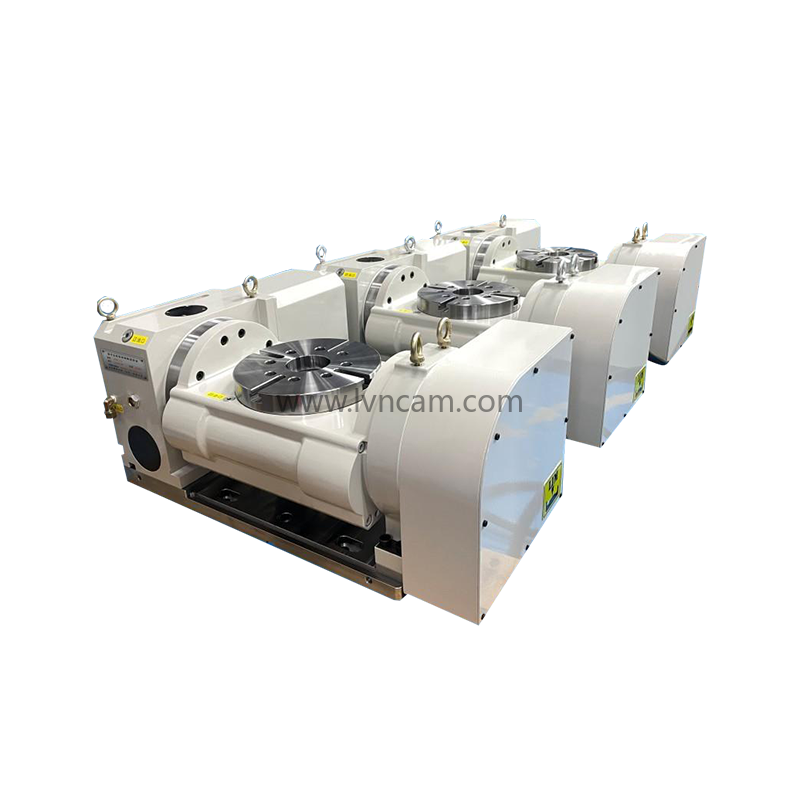

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow