news

What is the accuracy of the cam divider?2023-07-28The accuracy of the cam divider depends on many factors, such as the materials used, design and manufacturing process. Generally speaking, the accuracy of the cam divider can reach a range of tens to several microns. The specific accuracy requirements are determined according to the actual use requirements and may vary depending on the application field. If you have specific requirements for the accuracy of a specific cam divider, you can refer to the technical specifications of the relevant product or consult a professional manufacturer for more accurate information. In addition to materials, design and manufacturing process, there are other factors that will affect the accuracy of the cam divider. For example, the roundness, straightness and surface quality of the camshaft have an important influence on the accuracy of the divider. At the same time, environmental factors such as temperature and humidity when the cam divider is used will also affect its accuracy.

What is the accuracy of the cam divider?2023-07-28The accuracy of the cam divider depends on many factors, such as the materials used, design and manufacturing process. Generally speaking, the accuracy of the cam divider can reach a range of tens to several microns. The specific accuracy requirements are determined according to the actual use requirements and may vary depending on the application field. If you have specific requirements for the accuracy of a specific cam divider, you can refer to the technical specifications of the relevant product or consult a professional manufacturer for more accurate information. In addition to materials, design and manufacturing process, there are other factors that will affect the accuracy of the cam divider. For example, the roundness, straightness and surface quality of the camshaft have an important influence on the accuracy of the divider. At the same time, environmental factors such as temperature and humidity when the cam divider is used will also affect its accuracy. CNC lathe spindle indexing programming example2023-07-27When performing spindle indexing programming for a CNC lathe, we can use G codes and M codes to control the rotation of the spindle. The following is an example of a simple spindle indexing programming: 1. Suppose we want the spindle to rotate 6 workpiece angles, each workpiece angle is 60 degrees. 2. First, we need to set the CNC system to rotating spindle mode. We can use M codes to achieve this. At the beginning of the program, add a programming code: M3 S1000 (start the spindle and set the speed to 1000rpm). 3. Next, we need to perform spindle indexing programming. Assume that the current X-axis and Z-axis positions are both zero. We can use G codes and M codes to complete this process. In the middle part of the program, add the following programming code: G1 X0 Z0

CNC lathe spindle indexing programming example2023-07-27When performing spindle indexing programming for a CNC lathe, we can use G codes and M codes to control the rotation of the spindle. The following is an example of a simple spindle indexing programming: 1. Suppose we want the spindle to rotate 6 workpiece angles, each workpiece angle is 60 degrees. 2. First, we need to set the CNC system to rotating spindle mode. We can use M codes to achieve this. At the beginning of the program, add a programming code: M3 S1000 (start the spindle and set the speed to 1000rpm). 3. Next, we need to perform spindle indexing programming. Assume that the current X-axis and Z-axis positions are both zero. We can use G codes and M codes to complete this process. In the middle part of the program, add the following programming code: G1 X0 Z0 How to turn threads on a CNC lathe? What are the specific methods and steps?2023-07-26Threading on a lathe can be accomplished by following these steps: 1. Preparation: Confirm that the lathe is equipped with a thread cutter of the appropriate size and type. Make sure that the workpiece is clamped securely, the tool is functioning properly, and that the power and speed of the lathe are adjusted correctly. 2. Zero point setting: Use the CNC lathe's operating panel to set the tool position and zero point position to the position where the thread begins. Make sure that the coordinate system on the lathe is consistent with that of the CNC system. 3. Set the pitch, feed rate, and speed: Set the pitch, feed rate, and spindle speed according to the required thread specifications. These parameters can be calculated based on the type and size of the thread or consult the relevant manual for recommended values. 4. Perform rough turning: By adjusting the relative position of the workpiece and the tool,

How to turn threads on a CNC lathe? What are the specific methods and steps?2023-07-26Threading on a lathe can be accomplished by following these steps: 1. Preparation: Confirm that the lathe is equipped with a thread cutter of the appropriate size and type. Make sure that the workpiece is clamped securely, the tool is functioning properly, and that the power and speed of the lathe are adjusted correctly. 2. Zero point setting: Use the CNC lathe's operating panel to set the tool position and zero point position to the position where the thread begins. Make sure that the coordinate system on the lathe is consistent with that of the CNC system. 3. Set the pitch, feed rate, and speed: Set the pitch, feed rate, and spindle speed according to the required thread specifications. These parameters can be calculated based on the type and size of the thread or consult the relevant manual for recommended values. 4. Perform rough turning: By adjusting the relative position of the workpiece and the tool, Is lathe work tiring? Is it dangerous?2023-07-25Is lathe tiring? Is the work hard? Is it dangerous? The degree of fatigue and danger of lathe work depends on many factors, including the working environment, operating techniques and safety awareness. The following is a discussion of some relevant factors: 1. Workload: Lathe work usually requires long hours of operation, and may require long periods of alertness and concentration. For people who work in a sitting position for a long time, muscle fatigue and physical discomfort may occur. Therefore, it is important to take regular breaks and physical training to reduce fatigue. 2. Operating techniques: Correct operating techniques play an important role in reducing fatigue and danger. Proficiency in operating methods, correct use of tools and understanding of relevant safety regulations can effectively reduce accidental risks at work and dangers caused by incorrect operations.

Is lathe work tiring? Is it dangerous?2023-07-25Is lathe tiring? Is the work hard? Is it dangerous? The degree of fatigue and danger of lathe work depends on many factors, including the working environment, operating techniques and safety awareness. The following is a discussion of some relevant factors: 1. Workload: Lathe work usually requires long hours of operation, and may require long periods of alertness and concentration. For people who work in a sitting position for a long time, muscle fatigue and physical discomfort may occur. Therefore, it is important to take regular breaks and physical training to reduce fatigue. 2. Operating techniques: Correct operating techniques play an important role in reducing fatigue and danger. Proficiency in operating methods, correct use of tools and understanding of relevant safety regulations can effectively reduce accidental risks at work and dangers caused by incorrect operations. What is a lathe and what is it used for?2023-07-24A lathe is a machine tool used to process rotationally symmetrical parts. It is mainly used to process metal materials, but can also be used to process wood, plastic and other materials. The workpiece is fixed on the spindle and rotated, and then the workpiece is cut and trimmed with a cutting tool to achieve the desired shape and size. A lathe can perform a variety of operations, such as turning (mainly used for processing outer contours), boring (processing holes), drilling (for processing holes), grinding, grooving, etc. Lathes are widely used in the manufacturing industry to manufacture various parts, threads, shafts, gears and other rotationally symmetrical parts. It is an important precision processing equipment commonly found in industries such as machinery manufacturing, automobiles, aerospace, electronics and ships.

What is a lathe and what is it used for?2023-07-24A lathe is a machine tool used to process rotationally symmetrical parts. It is mainly used to process metal materials, but can also be used to process wood, plastic and other materials. The workpiece is fixed on the spindle and rotated, and then the workpiece is cut and trimmed with a cutting tool to achieve the desired shape and size. A lathe can perform a variety of operations, such as turning (mainly used for processing outer contours), boring (processing holes), drilling (for processing holes), grinding, grooving, etc. Lathes are widely used in the manufacturing industry to manufacture various parts, threads, shafts, gears and other rotationally symmetrical parts. It is an important precision processing equipment commonly found in industries such as machinery manufacturing, automobiles, aerospace, electronics and ships. How to remove the lathe chuck? What are the steps?2023-07-23To remove a lathe chuck, follow these steps: 1. First, make sure the lathe is stopped and the power is off. It is very important to operate safely. 2. Remove any workpiece or fixture from the chuck. 3. You may need to use special tools or wrenches and follow the manufacturer's operating manual or instructions. Different models of lathe chucks may have different removal methods. 4. Before removing the chuck, check and record the position of the chuck so that you can maintain the same positioning when reinstalling it.

How to remove the lathe chuck? What are the steps?2023-07-23To remove a lathe chuck, follow these steps: 1. First, make sure the lathe is stopped and the power is off. It is very important to operate safely. 2. Remove any workpiece or fixture from the chuck. 3. You may need to use special tools or wrenches and follow the manufacturer's operating manual or instructions. Different models of lathe chucks may have different removal methods. 4. Before removing the chuck, check and record the position of the chuck so that you can maintain the same positioning when reinstalling it. How to calculate the taper of CNC lathe? What is the formula?2023-07-22To calculate taper (an inclined or tapered workpiece surface) on a CNC lathe, you need to know the following parameters: 1. Workpiece length (L): The distance between the workpiece at the start and end points of the desired taper. 2. Workpiece diameter (D1 and D2): The diameter of the workpiece at the start and end points. 3. Taper angle (α): The desired taper angle, usually expressed in degrees. The taper can be calculated using the following formula: tan(α) = (D2 - D1) / L

How to calculate the taper of CNC lathe? What is the formula?2023-07-22To calculate taper (an inclined or tapered workpiece surface) on a CNC lathe, you need to know the following parameters: 1. Workpiece length (L): The distance between the workpiece at the start and end points of the desired taper. 2. Workpiece diameter (D1 and D2): The diameter of the workpiece at the start and end points. 3. Taper angle (α): The desired taper angle, usually expressed in degrees. The taper can be calculated using the following formula: tan(α) = (D2 - D1) / L What are the steps for tool setting on CNC lathe?2023-07-21Tool setting on a CNC lathe can be completed by following the steps below: 1. Preparation: Make sure the CNC lathe and tool holder are clean and free of any debris. Make sure the tool is installed correctly and firmly. 2. Zero point setting: Use the CNC lathe's operating panel to enter the tool setting mode. Select a suitable zero point position, such as the edge of the workpiece or an established reference point, and set it as the zero point. Make sure the coordinate system on the lathe is consistent with the coordinate system of the CNC system. 3. Execute the automatic tool setting program: CNC lathes are usually equipped with an automatic tool setting program. Running this program will automatically adjust the Z-axis and X-axis positions of the tool and measure at the set position. 4. Measure the tool length: The CNC lathe will automatically move the tool to the preset position and use a sensor or measuring tool to measure the tool length. This value will be automatically saved in the tool offset table of the CNC system. 5. Measure the tool diameter: Some CNC lathes can also obtain more accurate tool compensation values by measuring the tool diameter. At the specified position, use the measuring tool

What are the steps for tool setting on CNC lathe?2023-07-21Tool setting on a CNC lathe can be completed by following the steps below: 1. Preparation: Make sure the CNC lathe and tool holder are clean and free of any debris. Make sure the tool is installed correctly and firmly. 2. Zero point setting: Use the CNC lathe's operating panel to enter the tool setting mode. Select a suitable zero point position, such as the edge of the workpiece or an established reference point, and set it as the zero point. Make sure the coordinate system on the lathe is consistent with the coordinate system of the CNC system. 3. Execute the automatic tool setting program: CNC lathes are usually equipped with an automatic tool setting program. Running this program will automatically adjust the Z-axis and X-axis positions of the tool and measure at the set position. 4. Measure the tool length: The CNC lathe will automatically move the tool to the preset position and use a sensor or measuring tool to measure the tool length. This value will be automatically saved in the tool offset table of the CNC system. 5. Measure the tool diameter: Some CNC lathes can also obtain more accurate tool compensation values by measuring the tool diameter. At the specified position, use the measuring tool How to use a lathe? Operation tutorial for beginners2023-07-20Here are the basic steps for using a lathe and some tips for getting started: 1. Cleaning and preparation: Make sure the lathe is clean and remove any debris and dust. Check the condition of all mechanical parts to ensure that there is no wear or looseness. Install and tighten the work clamping device. 2. Install the tool: Select a suitable tool and install it on the tool holder of the lathe. Adjust the height and angle of the tool holder so that the tool can cut correctly when it contacts the workpiece. 3. Set up the workpiece: Install the workpiece to be processed on the workpiece clamping device of the lathe. Make sure the workpiece clamping device is firm to ensure the stability of the workpiece. 4. Adjust the lathe parameters: Adjust the speed, feed rate and cutting depth of the lathe according to the work requirements. Determine the appropriate parameters based on the hardness of the material and the size of the workpiece. For novices, it is recommended to start with a lower speed and feed rate to prevent the tool from losing control due to excessive cutting speed.

How to use a lathe? Operation tutorial for beginners2023-07-20Here are the basic steps for using a lathe and some tips for getting started: 1. Cleaning and preparation: Make sure the lathe is clean and remove any debris and dust. Check the condition of all mechanical parts to ensure that there is no wear or looseness. Install and tighten the work clamping device. 2. Install the tool: Select a suitable tool and install it on the tool holder of the lathe. Adjust the height and angle of the tool holder so that the tool can cut correctly when it contacts the workpiece. 3. Set up the workpiece: Install the workpiece to be processed on the workpiece clamping device of the lathe. Make sure the workpiece clamping device is firm to ensure the stability of the workpiece. 4. Adjust the lathe parameters: Adjust the speed, feed rate and cutting depth of the lathe according to the work requirements. Determine the appropriate parameters based on the hardness of the material and the size of the workpiece. For novices, it is recommended to start with a lower speed and feed rate to prevent the tool from losing control due to excessive cutting speed. How to add cam divider lubricating oil2023-07-19The lubrication of the cam divider has an important impact on its normal operation and life. The first is the oil filling process. Before using the divider, the oil filling operation must be carried out. However, during the oil filling process, the mixing of iron filings, oil residues and dust will cause wear of components such as cam ridges, bearings and rollers, thereby reducing the accuracy of the divider. Therefore, when filling the oil, you need to wipe the oil port clean first, and then use clean oil to inject it. The amount of oil filling should be in accordance with the requirements of the oil standard. The second is the time of oil change. The first oil change should be carried out after 1000 hours of operation, and the second oil change should be carried out within 3000 hours after the last oil change. Even if the operation time is shorter, the oil should be changed once a year. The viscosity coefficient of the lubricating oil used depends on the speed of the divider. The following is a reference table of the viscosity coefficient of the lubricating oil:- The speed range is 0-20 rpm, and the viscosity must be greater than 680 ct/40 °- The speed range is 20-100 rpm

How to add cam divider lubricating oil2023-07-19The lubrication of the cam divider has an important impact on its normal operation and life. The first is the oil filling process. Before using the divider, the oil filling operation must be carried out. However, during the oil filling process, the mixing of iron filings, oil residues and dust will cause wear of components such as cam ridges, bearings and rollers, thereby reducing the accuracy of the divider. Therefore, when filling the oil, you need to wipe the oil port clean first, and then use clean oil to inject it. The amount of oil filling should be in accordance with the requirements of the oil standard. The second is the time of oil change. The first oil change should be carried out after 1000 hours of operation, and the second oil change should be carried out within 3000 hours after the last oil change. Even if the operation time is shorter, the oil should be changed once a year. The viscosity coefficient of the lubricating oil used depends on the speed of the divider. The following is a reference table of the viscosity coefficient of the lubricating oil:- The speed range is 0-20 rpm, and the viscosity must be greater than 680 ct/40 °- The speed range is 20-100 rpm Shanghai Machine Tool Show 2023 will be held in Shanghai International Convention and Exhibition Center2023-07-18The Shanghai Machine Tool Show 2023 will be a grand event for the global machine tool industry and will be held at the Shanghai National Convention and Exhibition Center. The exhibition will attract leaders and professionals from the global machine tool industry to gather together to showcase world-class machine tool equipment and intelligent manufacturing applications, and promote technical exchanges and business cooperation. One of the highlights of the Shanghai Machine Tool Show 2023 is the concentrated display of the world's top machine tool equipment and emerging intelligent manufacturing technologies. The exhibition covers machine tools and parts, processing and forming machinery, industrial automation, robots, transmission technology, tools and measuring instruments, etc., bringing a wider range of choices to the audience. The exhibition will also showcase industry development trends and cutting-edge technologies. As a grand event in the machine tool industry, the Shanghai Machine Tool Show 2023 will provide industry experts and companies with opportunities to understand the overall development trends of the domestic and foreign machine tool markets, explore industry policies, and understand cutting-edge technologies.

Shanghai Machine Tool Show 2023 will be held in Shanghai International Convention and Exhibition Center2023-07-18The Shanghai Machine Tool Show 2023 will be a grand event for the global machine tool industry and will be held at the Shanghai National Convention and Exhibition Center. The exhibition will attract leaders and professionals from the global machine tool industry to gather together to showcase world-class machine tool equipment and intelligent manufacturing applications, and promote technical exchanges and business cooperation. One of the highlights of the Shanghai Machine Tool Show 2023 is the concentrated display of the world's top machine tool equipment and emerging intelligent manufacturing technologies. The exhibition covers machine tools and parts, processing and forming machinery, industrial automation, robots, transmission technology, tools and measuring instruments, etc., bringing a wider range of choices to the audience. The exhibition will also showcase industry development trends and cutting-edge technologies. As a grand event in the machine tool industry, the Shanghai Machine Tool Show 2023 will provide industry experts and companies with opportunities to understand the overall development trends of the domestic and foreign machine tool markets, explore industry policies, and understand cutting-edge technologies. What brands are there of manufacturers of ATC tools for CNC machine tools?2023-07-18There are many manufacturers of ATC tools for CNC machine tools. The following are some well-known brands of ATC tool manufacturers: 1. Sandvik Coromant: As a global leading supplier of tools and processing solutions, Sandvik Coromant provides a variety of cutting tools and tool systems, including ATC tools. 2. Kennametal: Kennametal is a global supplier of tools and tool systems, providing high-performance ATC tools for various CNC machine tool applications. 3. Iscar: Iscar is a global supplier of metal cutting tools, providing a variety of high-quality ATC tools.

What brands are there of manufacturers of ATC tools for CNC machine tools?2023-07-18There are many manufacturers of ATC tools for CNC machine tools. The following are some well-known brands of ATC tool manufacturers: 1. Sandvik Coromant: As a global leading supplier of tools and processing solutions, Sandvik Coromant provides a variety of cutting tools and tool systems, including ATC tools. 2. Kennametal: Kennametal is a global supplier of tools and tool systems, providing high-performance ATC tools for various CNC machine tool applications. 3. Iscar: Iscar is a global supplier of metal cutting tools, providing a variety of high-quality ATC tools. What are the power parameters of CNC machine tools? How to check them?2023-07-18As a editor in the machine tool industry, I am very happy to introduce you to the power parameters of machine tools. The power parameters of machine tools are some important indicators that describe the power performance and energy consumption characteristics of machine tools. The following are some common machine tool power parameters: 1. Spindle power (Main Spindle Power): Spindle power refers to the power required by the machine tool spindle, also known as the spindle drive power. It indicates the spindle drive capacity required by the machine tool during the machining process and is an important indicator for measuring the machining capability of the machine tool. 2. Spindle speed (Main Spindle Speed): Spindle speed refers to the speed at which the machine tool spindle rotates. The spindle speed is usually expressed in revolutions per minute (RPM), which determines the machining speed and cutting efficiency of the machine tool. For different types of machining processes, it is necessary to select the appropriate spindle speed according to the material and machining requirements. 3. Power factor (Power Factor)

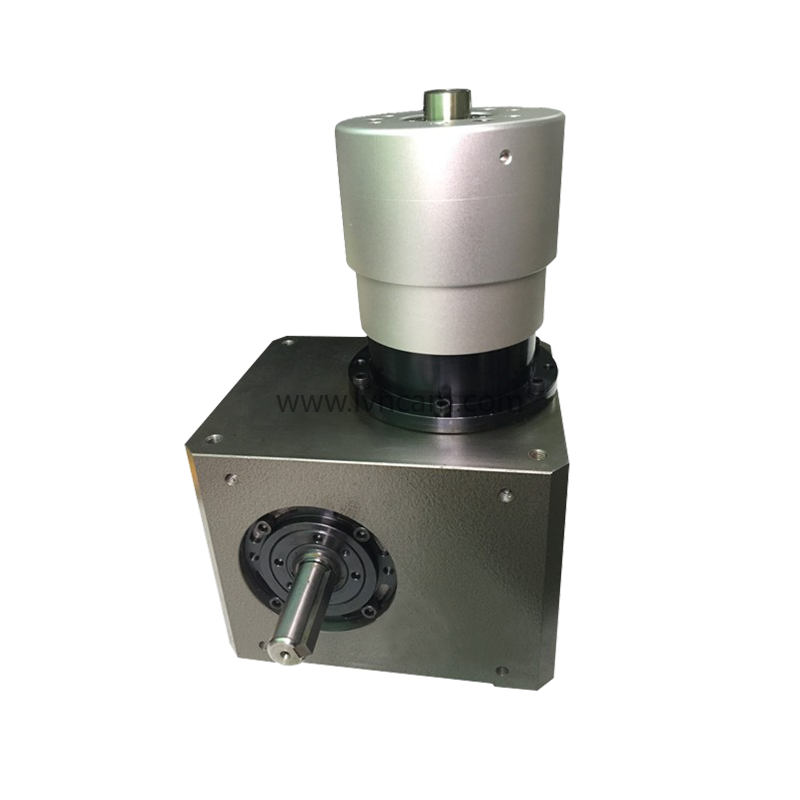

What are the power parameters of CNC machine tools? How to check them?2023-07-18As a editor in the machine tool industry, I am very happy to introduce you to the power parameters of machine tools. The power parameters of machine tools are some important indicators that describe the power performance and energy consumption characteristics of machine tools. The following are some common machine tool power parameters: 1. Spindle power (Main Spindle Power): Spindle power refers to the power required by the machine tool spindle, also known as the spindle drive power. It indicates the spindle drive capacity required by the machine tool during the machining process and is an important indicator for measuring the machining capability of the machine tool. 2. Spindle speed (Main Spindle Speed): Spindle speed refers to the speed at which the machine tool spindle rotates. The spindle speed is usually expressed in revolutions per minute (RPM), which determines the machining speed and cutting efficiency of the machine tool. For different types of machining processes, it is necessary to select the appropriate spindle speed according to the material and machining requirements. 3. Power factor (Power Factor) Structural principle and precautions of cam divider2023-07-18The structural principle of the cam divider and some common connection methods and precautions: 1. Input drive system connection: The driving parts connected to the divider input shaft include pulleys, sprockets, synchronous pulleys, gears and couplings. Since the camshaft torque has positive and negative changes in one week, and the cam characteristics can only work at a certain speed, unstable rotation will apply additional torque to the divider and have an adverse effect on intermittent motion. Therefore, sliding belts, pulsating chains or gear drives with gaps should not be used on the camshaft. When using belts or chains, expansion operations are required. When using gears, high precision must be ensured and meshing gaps must be eliminated. The use of synchronous belts has many advantages. It can achieve synchronization with other actions, no gaps are generated, less vibration and high-speed transmission can be achieved. In addition, the use of large-diameter pulleys can also provide a good flywheel effect. In general, the input shaft of the divider adopts a shaft input key connection structure. During the transmission process, due to the instability of various factors and the pulsation of the driving load, it is easy to cause the key connection to loosen,

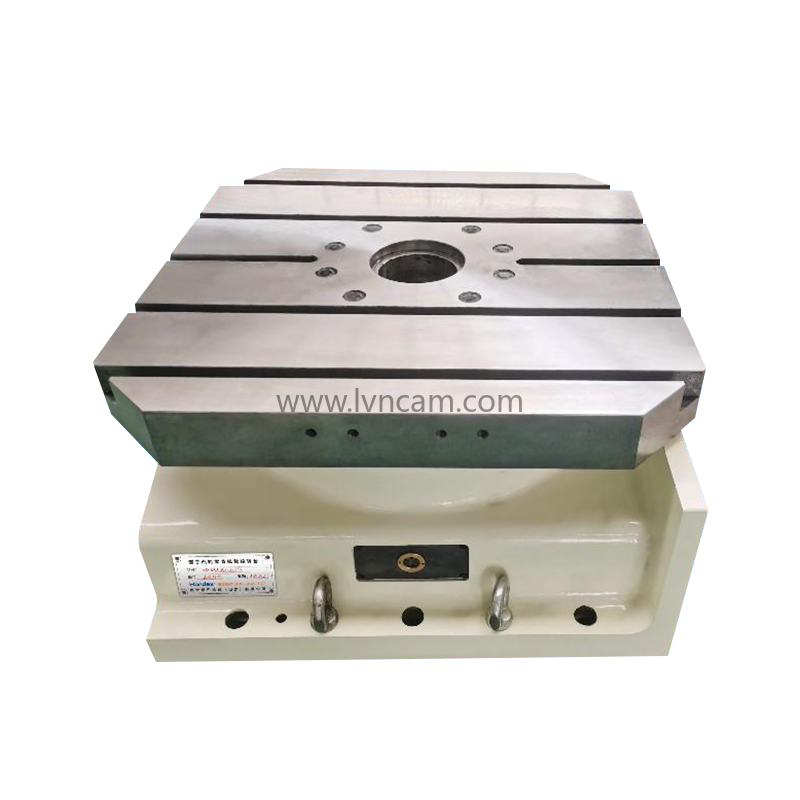

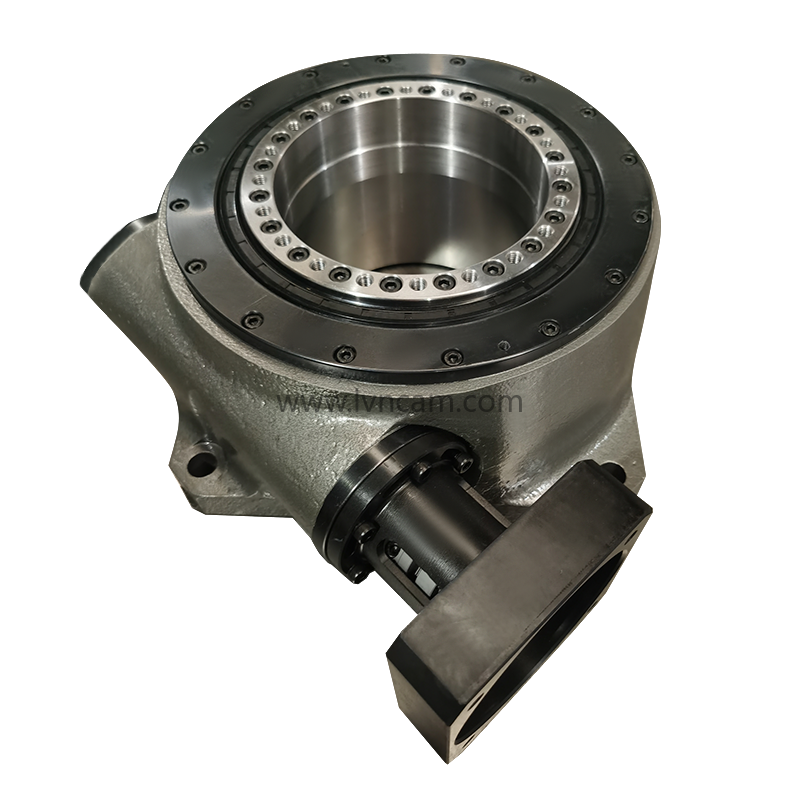

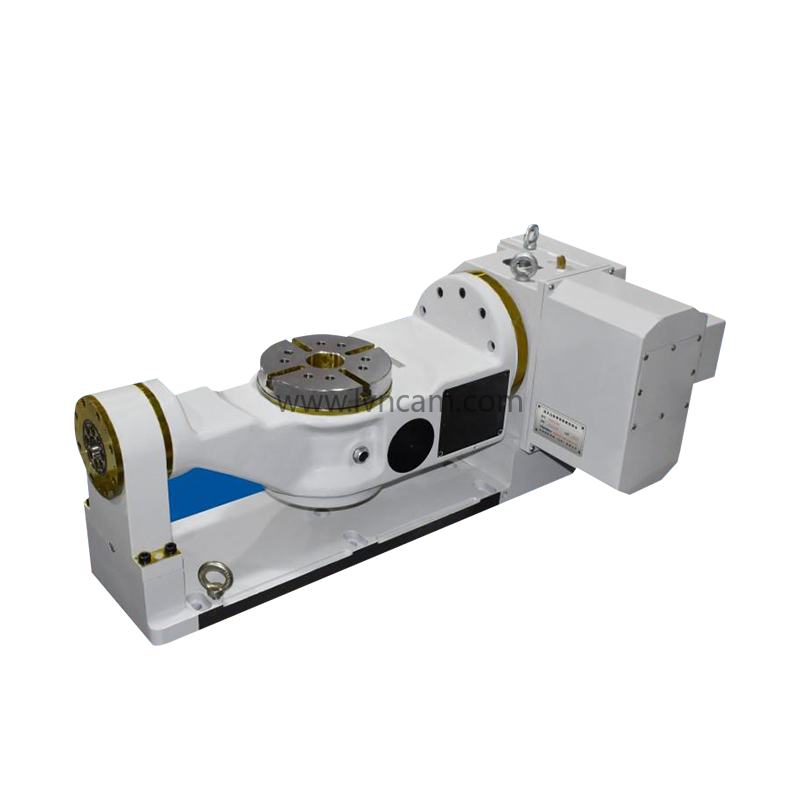

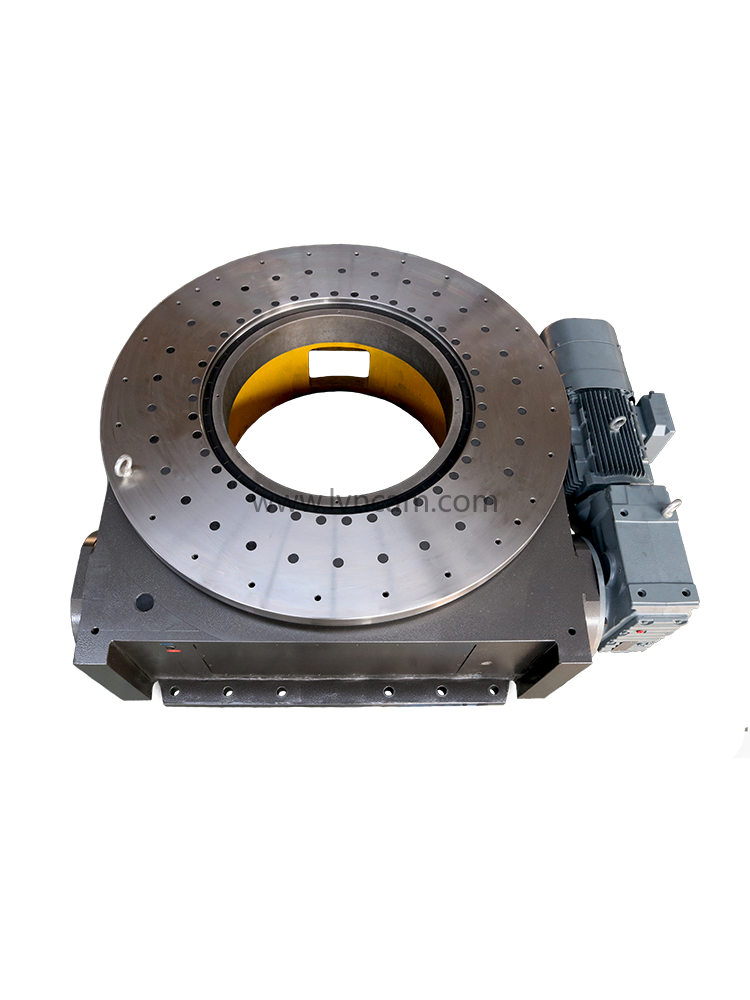

Structural principle and precautions of cam divider2023-07-18The structural principle of the cam divider and some common connection methods and precautions: 1. Input drive system connection: The driving parts connected to the divider input shaft include pulleys, sprockets, synchronous pulleys, gears and couplings. Since the camshaft torque has positive and negative changes in one week, and the cam characteristics can only work at a certain speed, unstable rotation will apply additional torque to the divider and have an adverse effect on intermittent motion. Therefore, sliding belts, pulsating chains or gear drives with gaps should not be used on the camshaft. When using belts or chains, expansion operations are required. When using gears, high precision must be ensured and meshing gaps must be eliminated. The use of synchronous belts has many advantages. It can achieve synchronization with other actions, no gaps are generated, less vibration and high-speed transmission can be achieved. In addition, the use of large-diameter pulleys can also provide a good flywheel effect. In general, the input shaft of the divider adopts a shaft input key connection structure. During the transmission process, due to the instability of various factors and the pulsation of the driving load, it is easy to cause the key connection to loosen, Hollow Rotary Platform Selection Steps2023-07-18The hollow rotary platform is one of the commonly used accessories on machine tools. When choosing a suitable hollow rotary platform, you need to go through the following steps: 1. Select the turntable size according to the size of the workpiece: Before selecting the model, you need to clarify the size requirements of the workpiece, including the calculation of parameters such as the diameter and weight of the workpiece. Select the appropriate turntable size according to the size of the workpiece to ensure that the workpiece can be completely placed on the turntable and has sufficient load-bearing capacity. 2. Determine the model based on the size of the turntable: According to the selected turntable size, you can find the corresponding hollow rotary platform model. The hollow rotary platforms of various models may differ in load-bearing capacity, rotation speed, accuracy, etc. You need to carefully compare the characteristics of each model and select the most suitable model.

Hollow Rotary Platform Selection Steps2023-07-18The hollow rotary platform is one of the commonly used accessories on machine tools. When choosing a suitable hollow rotary platform, you need to go through the following steps: 1. Select the turntable size according to the size of the workpiece: Before selecting the model, you need to clarify the size requirements of the workpiece, including the calculation of parameters such as the diameter and weight of the workpiece. Select the appropriate turntable size according to the size of the workpiece to ensure that the workpiece can be completely placed on the turntable and has sufficient load-bearing capacity. 2. Determine the model based on the size of the turntable: According to the selected turntable size, you can find the corresponding hollow rotary platform model. The hollow rotary platforms of various models may differ in load-bearing capacity, rotation speed, accuracy, etc. You need to carefully compare the characteristics of each model and select the most suitable model.

{item.title}

{item.publish_time}

{item.description}

Industry Information

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

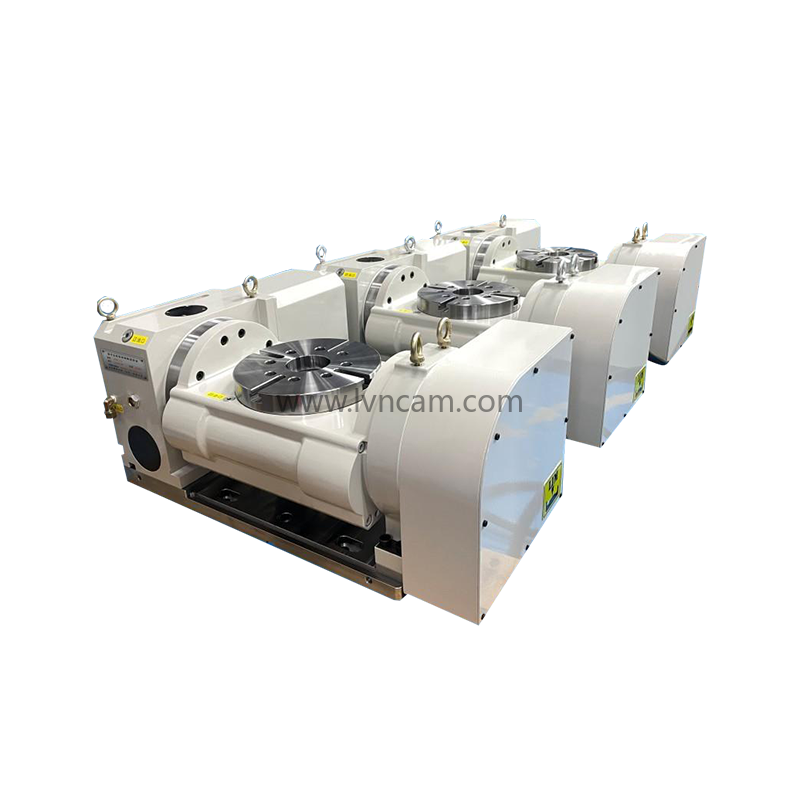

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow