news

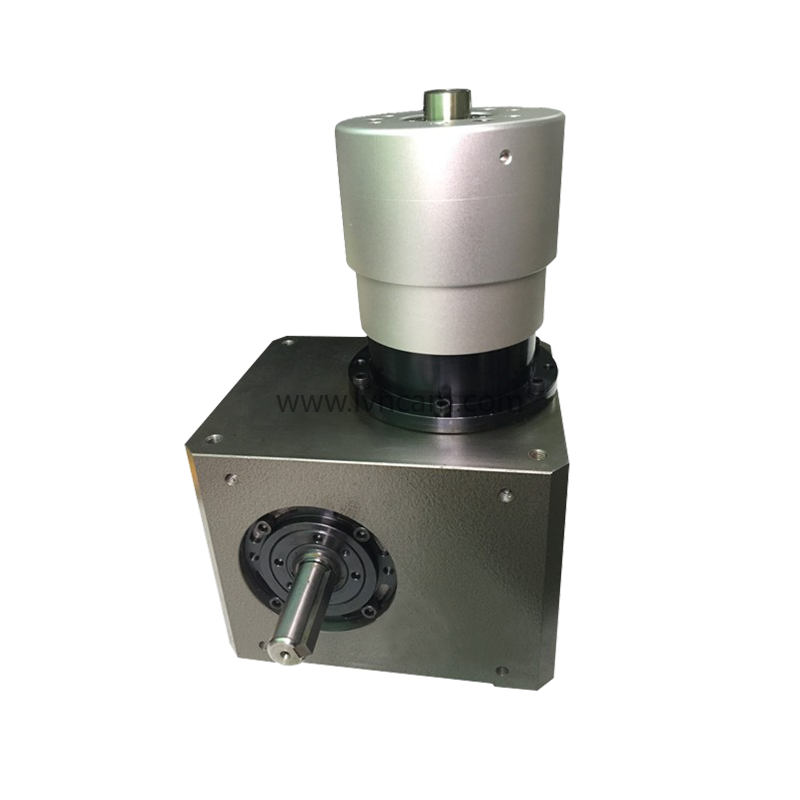

What is the difference between a CNC turntable and a rotor shaft?2023-09-16The CNC turntable and the rotor shaft are closely related. As the core transmission part of the coupling, the rotor shaft connects the motor or other transmission device and the CNC turntable, and plays the role of transmitting rotational force and torque. Reasonable selection and maintenance of the rotor shaft can ensure the normal operation and processing effect of the CNC turntable.

What is the difference between a CNC turntable and a rotor shaft?2023-09-16The CNC turntable and the rotor shaft are closely related. As the core transmission part of the coupling, the rotor shaft connects the motor or other transmission device and the CNC turntable, and plays the role of transmitting rotational force and torque. Reasonable selection and maintenance of the rotor shaft can ensure the normal operation and processing effect of the CNC turntable. Application of cam divider in grouting construction industry2023-09-09Cam dividers are often used in the grouting construction industry to reinforce anchor bolt holes or fill gaps to enhance the stability and bearing capacity of the foundation. This article introduces the timing and requirements of primary and secondary grouting, as well as the precautions for anchor bolt grouting and through-type anchor bolt hole grouting.

Application of cam divider in grouting construction industry2023-09-09Cam dividers are often used in the grouting construction industry to reinforce anchor bolt holes or fill gaps to enhance the stability and bearing capacity of the foundation. This article introduces the timing and requirements of primary and secondary grouting, as well as the precautions for anchor bolt grouting and through-type anchor bolt hole grouting. "Breaking the boundaries of technology: Camshaft innovation is leading the automotive industry"2023-09-01The camshaft is a mechanical device that converts rotary motion into reciprocating motion. It controls the opening and closing of the intake and exhaust valves, fuel injection, and driving transmission devices to achieve the normal operation of the engine. The camshaft plays an important role in the automotive industry and directly affects the performance and efficiency of the engine. Through continuous technological innovation and optimization, the camshaft provides more efficient and environmentally friendly solutions for the automotive industry.

"Breaking the boundaries of technology: Camshaft innovation is leading the automotive industry"2023-09-01The camshaft is a mechanical device that converts rotary motion into reciprocating motion. It controls the opening and closing of the intake and exhaust valves, fuel injection, and driving transmission devices to achieve the normal operation of the engine. The camshaft plays an important role in the automotive industry and directly affects the performance and efficiency of the engine. Through continuous technological innovation and optimization, the camshaft provides more efficient and environmentally friendly solutions for the automotive industry. Unleashing precision: the potential of cam indexers in engineering2023-08-31Cam dividers have great potential in the field of engineering. Through precise control, they can improve the accuracy, control and efficiency of robots. The principle of cam dividers is to achieve the precise motion trajectory of robots through the design and control of cam shafts and cam wheels. It is widely used in automatic assembly lines, robot handling, precision machining, medical surgery and other fields. The advantages of cam dividers include high accuracy, flexibility and programmability. With the innovation and development of technology, cam dividers will play a greater role in the field of engineering.

Unleashing precision: the potential of cam indexers in engineering2023-08-31Cam dividers have great potential in the field of engineering. Through precise control, they can improve the accuracy, control and efficiency of robots. The principle of cam dividers is to achieve the precise motion trajectory of robots through the design and control of cam shafts and cam wheels. It is widely used in automatic assembly lines, robot handling, precision machining, medical surgery and other fields. The advantages of cam dividers include high accuracy, flexibility and programmability. With the innovation and development of technology, cam dividers will play a greater role in the field of engineering. History and Importance of Camshafts2023-08-26The main focus is on the historical background and importance of camshafts. Camshafts, as a mechanical device, originated in ancient civilizations and were first used to produce specific sounds and tones. With the advent of the Industrial Revolution, the application range of camshafts has expanded and they have become an indispensable component in many mechanical devices and engines. Camshafts play a key role in the automotive industry as well as in the fields of shipping, aviation, energy, and mechanical industries. With the advancement of science and technology, the design and manufacture of camshafts have been greatly improved. Innovations in material science, manufacturing technology, and electronic control systems have made camshafts more durable, able to withstand high speeds and high temperatures, and can more accurately control the operation of the engine's valves, improving the performance and fuel efficiency of the car.

History and Importance of Camshafts2023-08-26The main focus is on the historical background and importance of camshafts. Camshafts, as a mechanical device, originated in ancient civilizations and were first used to produce specific sounds and tones. With the advent of the Industrial Revolution, the application range of camshafts has expanded and they have become an indispensable component in many mechanical devices and engines. Camshafts play a key role in the automotive industry as well as in the fields of shipping, aviation, energy, and mechanical industries. With the advancement of science and technology, the design and manufacture of camshafts have been greatly improved. Innovations in material science, manufacturing technology, and electronic control systems have made camshafts more durable, able to withstand high speeds and high temperatures, and can more accurately control the operation of the engine's valves, improving the performance and fuel efficiency of the car. "The Secret of the Camshaft: Dissecting Its Internal Structure and Construction"2023-08-25The camshaft is a mechanical device commonly used in internal combustion engines, generators and mechanical motion control systems. It consists of a shaft body and a cam. The shaft body is usually made of alloy steel, which bears the load and supports both ends through bearings to ensure stable rotation. The shape and position of the cam of the camshaft determine the motion characteristics, such as lifting height, lifting time, etc. The manufacturing process adopts mechanical processing technology to ensure the accuracy of the shaft body and the accuracy of the cam. During installation and adjustment, it is necessary to correctly locate the profile of the cam and the support position of the shaft body to ensure the normal operation of the camshaft. In short, the composition and structure of the camshaft have an important influence on its function and performance. Correctly understanding and applying the characteristics of the camshaft will help design and manufacture better products.

"The Secret of the Camshaft: Dissecting Its Internal Structure and Construction"2023-08-25The camshaft is a mechanical device commonly used in internal combustion engines, generators and mechanical motion control systems. It consists of a shaft body and a cam. The shaft body is usually made of alloy steel, which bears the load and supports both ends through bearings to ensure stable rotation. The shape and position of the cam of the camshaft determine the motion characteristics, such as lifting height, lifting time, etc. The manufacturing process adopts mechanical processing technology to ensure the accuracy of the shaft body and the accuracy of the cam. During installation and adjustment, it is necessary to correctly locate the profile of the cam and the support position of the shaft body to ensure the normal operation of the camshaft. In short, the composition and structure of the camshaft have an important influence on its function and performance. Correctly understanding and applying the characteristics of the camshaft will help design and manufacture better products. "Exploring the Secrets of Five-Axis Machining Center: The Ultimate Tool for Unlocking Complex Surface Machining"2023-08-23The CNC five-axis machining center equipment combines high speed and high rigidity, multi-angle and multi-dimensional machining processes, one clamping, and can complete the production and processing requirements of complex curved surfaces in one go, improving production efficiency and production accuracy. Five-axis machining centers are widely used in the production of aerospace, rail transportation, and new energy. The five axes of the five-axis machining center usually refer to the two rotary axes added by the CNC machine tool on the three common linear axes of X, Y, and Z to meet the processing needs of various products. The five-axis machining center can use any two of these rotary axes, depending on the configuration. It can use shorter cutting tools and achieve higher cutting speeds without applying excessive load to the tool, extending tool life and reducing breakage. In addition, the use of a five-axis machining center can process extremely complex parts from the entity, saving time and cost. In addition, the five-axis machining center can also save a lot of drilling time. In summary, the use of five-axis machining centers can improve processing efficiency and production accuracy, is suitable for complex surface processing, and is widely used in aerospace, rail transportation, and new energy fields.

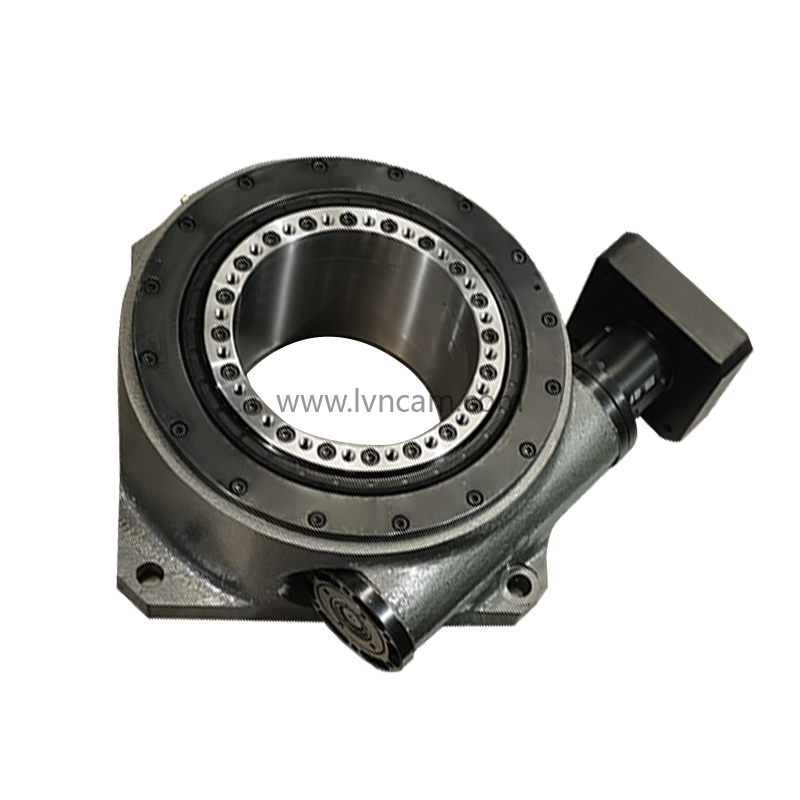

"Exploring the Secrets of Five-Axis Machining Center: The Ultimate Tool for Unlocking Complex Surface Machining"2023-08-23The CNC five-axis machining center equipment combines high speed and high rigidity, multi-angle and multi-dimensional machining processes, one clamping, and can complete the production and processing requirements of complex curved surfaces in one go, improving production efficiency and production accuracy. Five-axis machining centers are widely used in the production of aerospace, rail transportation, and new energy. The five axes of the five-axis machining center usually refer to the two rotary axes added by the CNC machine tool on the three common linear axes of X, Y, and Z to meet the processing needs of various products. The five-axis machining center can use any two of these rotary axes, depending on the configuration. It can use shorter cutting tools and achieve higher cutting speeds without applying excessive load to the tool, extending tool life and reducing breakage. In addition, the use of a five-axis machining center can process extremely complex parts from the entity, saving time and cost. In addition, the five-axis machining center can also save a lot of drilling time. In summary, the use of five-axis machining centers can improve processing efficiency and production accuracy, is suitable for complex surface processing, and is widely used in aerospace, rail transportation, and new energy fields. Connecting Everything: The Magical Application of Hollow Rotating Platform in Connecting Components2023-08-18Hollow rotary platform: definition, classification, working principle and application results. The hollow rotary platform is a turntable device with a hollow structure. Through a precise transmission device and control system, it can achieve high-speed and precise rotational motion, and realize the transmission function of liquid, gas, cable, etc. through the center hole. The classification of hollow rotary platforms includes hollow rotary gear rings, hollow rotary joints, hollow rotary bearings and hollow rotary drives. Its application results are rich and varied, and it is widely used in mechanical manufacturing, aerospace, electronics, medical and other fields. With its diverse functions and improved efficiency, the hollow rotary platform provides a higher level of work efficiency for various industries.

Connecting Everything: The Magical Application of Hollow Rotating Platform in Connecting Components2023-08-18Hollow rotary platform: definition, classification, working principle and application results. The hollow rotary platform is a turntable device with a hollow structure. Through a precise transmission device and control system, it can achieve high-speed and precise rotational motion, and realize the transmission function of liquid, gas, cable, etc. through the center hole. The classification of hollow rotary platforms includes hollow rotary gear rings, hollow rotary joints, hollow rotary bearings and hollow rotary drives. Its application results are rich and varied, and it is widely used in mechanical manufacturing, aerospace, electronics, medical and other fields. With its diverse functions and improved efficiency, the hollow rotary platform provides a higher level of work efficiency for various industries. Exploring the secrets of CNC rotary tables: working principles and application prospects2023-08-18CNC rotary table is an automation equipment widely used in the field of industrial manufacturing. Through program control and precision transmission system, it can realize the rotation, positioning and processing of workpieces in a plane or in space. It can improve production efficiency, reduce labor costs, and improve processing accuracy and repeatability, and is suitable for a variety of materials and processes.

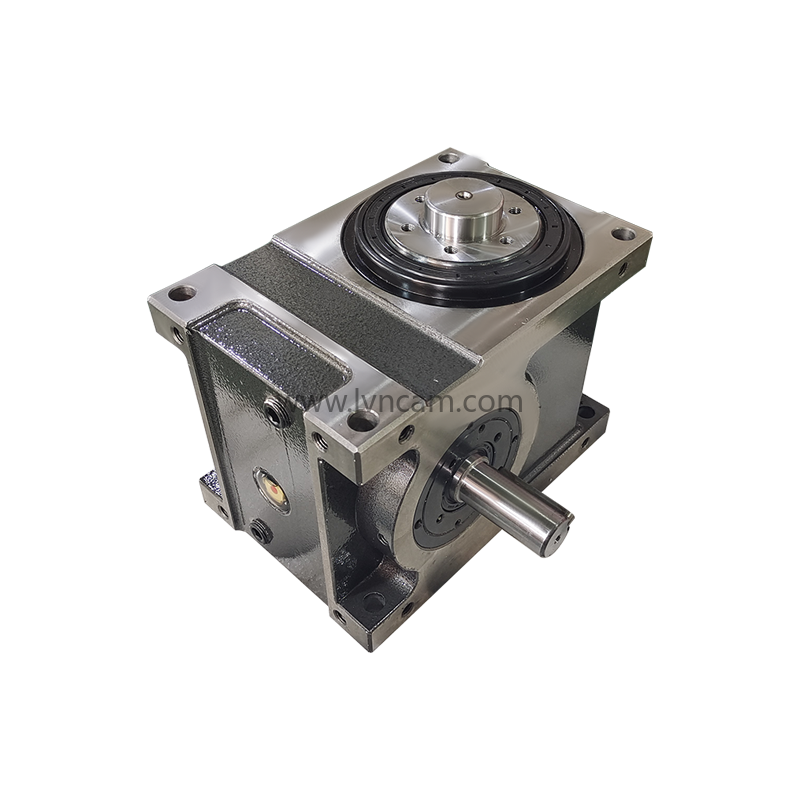

Exploring the secrets of CNC rotary tables: working principles and application prospects2023-08-18CNC rotary table is an automation equipment widely used in the field of industrial manufacturing. Through program control and precision transmission system, it can realize the rotation, positioning and processing of workpieces in a plane or in space. It can improve production efficiency, reduce labor costs, and improve processing accuracy and repeatability, and is suitable for a variety of materials and processes. Cam divider: the magic key to an engineering miracle, revealing its precise principle2023-08-18The cam divider is a mechanical device that can divide a continuously rotating disc into equally spaced parts. It consists of a cam and a groove, and achieves the dividing function through a sophisticated design and a drive device. The shape of the cam and the layout of the grooves determine the shape and number of the divided discs. The cam divider has a wide range of applications in the fields of engineering and manufacturing, providing important support for connecting machinery and creativity.

Cam divider: the magic key to an engineering miracle, revealing its precise principle2023-08-18The cam divider is a mechanical device that can divide a continuously rotating disc into equally spaced parts. It consists of a cam and a groove, and achieves the dividing function through a sophisticated design and a drive device. The shape of the cam and the layout of the grooves determine the shape and number of the divided discs. The cam divider has a wide range of applications in the fields of engineering and manufacturing, providing important support for connecting machinery and creativity. Introduction to the Function and Principle of CNC Device2023-08-17The CNC device is a key component in modern CNC machine tools. It realizes multiple control functions such as point control, linear control and continuous trajectory control through program reading devices and electronic circuits. Point control is used for precise positioning and fixed-point processing, linear control realizes linear cutting on the basis of point control, and continuous trajectory control can realize complex curve contour processing. The application of CNC devices enables CNC machine tools to have high-precision and high-efficiency processing capabilities, bringing huge development opportunities to the modern manufacturing industry.

Introduction to the Function and Principle of CNC Device2023-08-17The CNC device is a key component in modern CNC machine tools. It realizes multiple control functions such as point control, linear control and continuous trajectory control through program reading devices and electronic circuits. Point control is used for precise positioning and fixed-point processing, linear control realizes linear cutting on the basis of point control, and continuous trajectory control can realize complex curve contour processing. The application of CNC devices enables CNC machine tools to have high-precision and high-efficiency processing capabilities, bringing huge development opportunities to the modern manufacturing industry. The five major components and functions of CNC machine tools2023-08-16CNC machine tools are composed of control systems, servo systems, detection systems, mechanical transmission systems and other auxiliary systems. The control system is responsible for calculating, managing and controlling the movement of the machine tool, the servo system converts instructions into motion instructions, the detection system ensures the accuracy of the machine tool operation, the mechanical transmission system realizes the movement of the machine tool, and other auxiliary systems improve the performance and flexibility of the machine tool. These components work together to achieve precise processing and efficient production of CNC machine tools.

The five major components and functions of CNC machine tools2023-08-16CNC machine tools are composed of control systems, servo systems, detection systems, mechanical transmission systems and other auxiliary systems. The control system is responsible for calculating, managing and controlling the movement of the machine tool, the servo system converts instructions into motion instructions, the detection system ensures the accuracy of the machine tool operation, the mechanical transmission system realizes the movement of the machine tool, and other auxiliary systems improve the performance and flexibility of the machine tool. These components work together to achieve precise processing and efficient production of CNC machine tools. CNC technology - a powerful tool to enhance the core competitiveness of manufacturing industry!2023-08-14The application of CNC technology in the metal processing industry is becoming more and more widespread, especially CNC grinders in my country are at a good level. They remove materials by cutting to achieve high-precision and complex parts processing. Compared with traditional processing methods, CNC technology has higher efficiency, higher precision and better adaptability. At the same time, CNC equipment is easy to operate, only programming and parameter input are required, which reduces human involvement. However, the development of CNC technology also needs to be combined with the training and transformation of workers to achieve the best production benefits. Overall, the application of CNC technology has brought modernization and efficiency to the metal processing industry.

CNC technology - a powerful tool to enhance the core competitiveness of manufacturing industry!2023-08-14The application of CNC technology in the metal processing industry is becoming more and more widespread, especially CNC grinders in my country are at a good level. They remove materials by cutting to achieve high-precision and complex parts processing. Compared with traditional processing methods, CNC technology has higher efficiency, higher precision and better adaptability. At the same time, CNC equipment is easy to operate, only programming and parameter input are required, which reduces human involvement. However, the development of CNC technology also needs to be combined with the training and transformation of workers to achieve the best production benefits. Overall, the application of CNC technology has brought modernization and efficiency to the metal processing industry. The rise of CNC technology: changing the foundation of modern mechanical automation2023-08-13Since the mid-20th century, with the development of electronic technology and the emergence of electronic computers, CNC technology that uses digital signals to control the movement and processing of machine tools has gradually emerged. From the earliest digital mechanical processing to the emergence of CNC systems, and then to the development of point control and machining centers, CNC machine tools have played an increasingly important role in the field of automation. With the advancement of microelectronics technology, CNC machine tools have become more popular and cheaper, becoming the basic technology of modern mechanical automation, and flexible manufacturing systems have also been widely used. To this day, CNC technology is still developing and gradually expanding to various fields, from small and medium-sized batch processing to large-scale processing, bringing more efficient, precise and flexible solutions to industrial production.

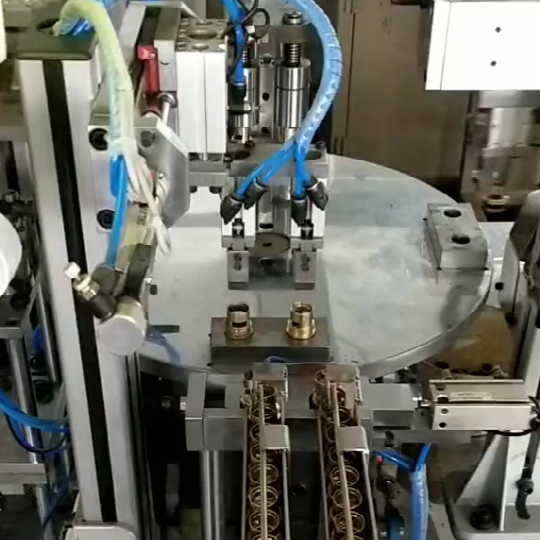

The rise of CNC technology: changing the foundation of modern mechanical automation2023-08-13Since the mid-20th century, with the development of electronic technology and the emergence of electronic computers, CNC technology that uses digital signals to control the movement and processing of machine tools has gradually emerged. From the earliest digital mechanical processing to the emergence of CNC systems, and then to the development of point control and machining centers, CNC machine tools have played an increasingly important role in the field of automation. With the advancement of microelectronics technology, CNC machine tools have become more popular and cheaper, becoming the basic technology of modern mechanical automation, and flexible manufacturing systems have also been widely used. To this day, CNC technology is still developing and gradually expanding to various fields, from small and medium-sized batch processing to large-scale processing, bringing more efficient, precise and flexible solutions to industrial production. Redefining automation: 10 fascinating applications of cam dividers in robotics2023-08-12Cam dividers have a wide range of applications in the field of robotics, including automatic assembly lines, robot handling, precision machining, arranging and packaging, polishing and polishing, assembly and disassembly, medical surgery, high-precision measurement, precision 3D printing and artificial intelligence interaction. It improves the accuracy, control and efficiency of robots by controlling the motion trajectory. The application of cam dividers continues to innovate and develop, bringing new breakthroughs and changes to the advancement and application promotion of robotics technology.

Redefining automation: 10 fascinating applications of cam dividers in robotics2023-08-12Cam dividers have a wide range of applications in the field of robotics, including automatic assembly lines, robot handling, precision machining, arranging and packaging, polishing and polishing, assembly and disassembly, medical surgery, high-precision measurement, precision 3D printing and artificial intelligence interaction. It improves the accuracy, control and efficiency of robots by controlling the motion trajectory. The application of cam dividers continues to innovate and develop, bringing new breakthroughs and changes to the advancement and application promotion of robotics technology.

{item.title}

{item.publish_time}

{item.description}

Industry Information

- 2024 Dragon Boat Festival Holiday Notice

- LN125R roller cam CNC turntable servo turntable real shot

- 180DT-4-270R LVNCAM cam divider real shot

- I wish that spring will be peaceful and prosperous, and that people on earth and in heaven will be safe and sound.

- 2024 Qingming Festival Holiday Notice

- Shandong Luning Precision Machinery Co., Ltd. wishes everyone a happy Lantern Festival.

- 110DT-8-270R-T30 cam divider input shaft extension motor plate

- Spring Festival Holiday Notice-Shandong Luning Precision Machinery Co., Ltd.

- Why are cam dividers so popular in production?

- What should we pay attention to when cleaning and maintaining the cam divider?

- Domestic brand cam dividers: good quality, low price and can meet high requirements

- LN170-36-24S 170 four-axis CNC rotary table four parallel use case

- L80DT-8-LN003 Customer Selection Case

- L60DF-6-LN002 flange type cam divider six positions

- L140DT-6-LN001 Shandong Luning Platform Desktop Intermittent Cam Divider Six-station Large Hollow